1. Okwu mmalite

Ịdị arọ ụgbọ ala malitere na mba ndị mepere emepe ma ndị dike ọgbara ọhụrụ na-eduzi ya na mbụ. Site na mmepe na-aga n'ihu, ọ nwetala nnukwu ume. Site na mgbe ndị India mbụ jiri aluminum alloy na-emepụta ụgbọ ala crankshafts na Audi mbụ uka mmepụta nke niile-aluminom ụgbọ ala na 1999, aluminum alloy ahụwo siri ike na-eto eto na ụgbọ ala ngwa n'ihi uru ya dị ka obere njupụta, elu kpọmkwem ike na isi ike, ezi elasticity na mmetụta na-eguzogide, elu recyclability, elu recyclability, na elu recyclability. Ka ọ na-erule afọ 2015, ntinye ngwa nke aluminom alloy n'ime ụgbọ ala agafeela 35%.

Igwe ọkụ ụgbọ ala China malitere ihe na-erughị afọ 10 gara aga, ma teknụzụ na ọkwa ngwa dị n'azụ mba ndị mepere emepe dị ka Germany, United States, na Japan. Agbanyeghị, site na mmepe nke ụgbọ ala ume ọhụrụ, ihe dị arọ na-aga n'ihu ngwa ngwa. N'ịkwalite ịrị elu nke ụgbọ ala ume ọhụrụ, teknụzụ ụgbọ ala China na-agba ọsọ na-egosi usoro nke ịchụkwudo mba ndị mepere emepe.

Ahịa ngwa ngwa nke China buru ibu. N'otu aka ahụ, e jiri ya tụnyere mba ndị mepere emepe na mba ọzọ, nkà na ụzụ China na-ebufe ibu malitere n'oge, na n'ozuzu ụgbọ ala Curb arọ bụ ibu. N'ịtụle nrịbama nke oke ihe ndị dị fechaa na mba ọzọ, a ka nwere ohere zuru oke maka mmepe na China. N'aka nke ọzọ, site na atumatu, mmepe ngwa ngwa nke ụlọ ọrụ ụgbọ ala ọhụrụ nke China ga-eme ka ọchịchọ maka ihe ndị dị arọ na-agba ume ma gbaa ụlọ ọrụ ụgbọ ala ume ịkwaga n'ịdị arọ.

Mmụba nke ikuku ikuku na ụkpụrụ oriri mmanụ na-amanye ngwa ngwa nke ịdị arọ ụgbọ ala. China mejuputa iwu nke China VI n'ụzọ zuru oke na 2020. Dị ka "Usoro nyocha na ihe ngosi maka oriri mmanụ ụgbọala nke ndị njem" na "Energy Saving and New Energy Vehicle Technology Roadmap," ụkpụrụ oriri mmanụ 5.0 L / km. N'iburu n'uche ohere dị ntakịrị maka nnukwu ọganiihu na teknụzụ injinia na mbelata ikuku ikuku, ime usoro maka ngwa ụgbọ ala dị fechaa nwere ike ibelata ikuku ụgbọ ala yana oriri mmanụ. Ịdị arọ nke ụgbọ ala ike ọhụrụ abụrụla ụzọ dị mkpa maka mmepe ụlọ ọrụ ahụ.

Na 2016, China Automotive Engineering Society nyere "Energy Saving and New Energy Vehicle Technology Roadmap," bụ nke zubere ihe ndị dị ka ike oriri ike, njem ụgbọ mmiri, na mmepụta ihe maka ụgbọ ala ike ọhụrụ site na 2020 ruo 2030. Ịtụ ọkụ ga-abụ isi ntụziaka maka ọdịnihu mmepe nke ụgbọ ala ike ọhụrụ. Ịfefe ibu nwere ike ịbawanye oke ịkwọ ụgbọ mmiri wee dozie "oke nchegbu" n'ime ụgbọ ala ume ọhụrụ. Site n'ọchịchọ na-arịwanye elu maka ogologo njem ụgbọ mmiri agbatịkwuru, ịfefe ụgbọ ala na-aghọ ngwa ngwa, na ire ụgbọ ala ume ọhụrụ etoola nke ukwuu n'afọ ndị na-adịbeghị anya. Dị ka ihe chọrọ nke usoro akara na "Mid-to-Long-Term Development Plan for the Automotive Industry," a na-eme atụmatụ na ka ọ na-erule 2025, ire China nke ụgbọ ala ume ọhụrụ ga-agafe nkeji 6 nde, yana mmụba kwa afọ na-eto eto karịa 38%.

2.Aluminium Alloy Characteristics and Applications

2.1 Njirimara nke Aluminom Alloy

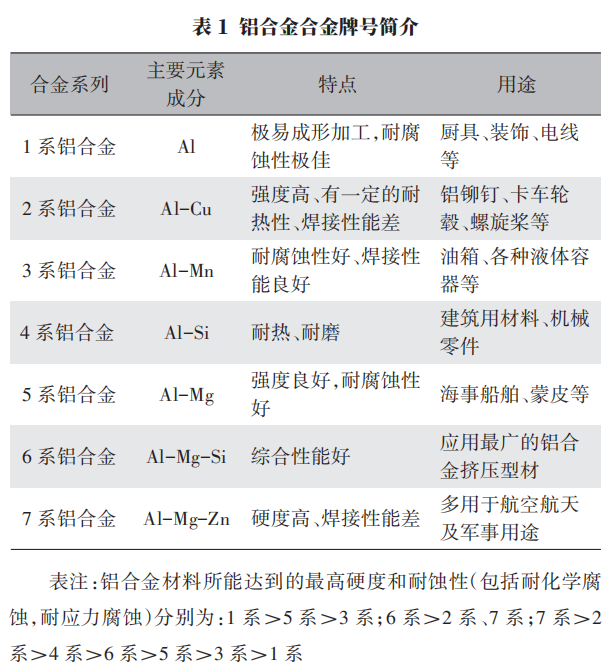

Njupụta nke aluminom bụ otu ụzọ n'ụzọ atọ nke ígwè, na-eme ka ọ dị ọkụ. Ọ nwere ike akọwapụtara nke ọma, ikike extrusion dị mma, nguzogide corrosion siri ike, yana nnukwu nrụpụta. A na-eji ihe ndị a na-emepụta ihe na-eme ka aluminom mee ihe site na isi ihe mejupụtara magnesium, na-egosipụta ezigbo nguzogide okpomọkụ, ezigbo ihe ịgbado ọkụ, ike ike ọgwụgwụ dị mma, enweghị ike ịme ka ọ dị ike site na ọgwụgwọ okpomọkụ, na ike ịbawanye ike site na ịrụ ọrụ oyi. A na-eji usoro nke 6 ahụ bụ nke mejupụtara magnesium na silicon, yana Mg2Si dị ka isi ihe na-ewusi ike. Alloy ndị a na-ejikarị eme ihe n'ụdị a bụ 6063, 6061, na 6005A. 5052 aluminum plate bụ ihe AL-Mg usoro alloy aluminum efere, na magnesium dị ka isi alloying element. Ọ bụ aluminom alloy na-emegide nchara nke a na-ejikarị eme ihe. Alloy a nwere ike dị elu, ike ike dị elu, ezigbo plasticity na corrosion resistance, enweghị ike ime ka ọ dị ike site na ọgwụgwọ okpomọkụ, nwere ezigbo plasticity na ọkara oyi na-arụ ọrụ siri ike, obere plasticity na-arụ ọrụ oyi na-arụ ọrụ oyi, ezigbo nkwụsị nke corrosion, na ezigbo ịgbado ọkụ. A na-ejikarị ya eme ihe dị ka akụkụ akụkụ, ihe mkpuchi ụlọ, na ọnụ ụzọ. 6063 aluminum alloy bụ ihe na-eme ka okpomọkụ na-eme ka ọ dị ike na usoro AL-Mg-Si, yana magnesium na silicon dị ka isi ihe na-eme ka ọ dị elu. Ọ bụ profaịlụ aluminom alloy na-eme ka okpomọkụ na-eme ka ike sie ike na ike ọkara, nke a na-ejikarị eme ihe n'usoro nhazi dịka ogidi na akụkụ akụkụ iji buru ike. E gosipụtara mmalite maka akara ule aluminom na tebụl 1.

2.2 Extrusion bụ ihe dị mkpa akpụ ụzọ nke Aluminom Alloy

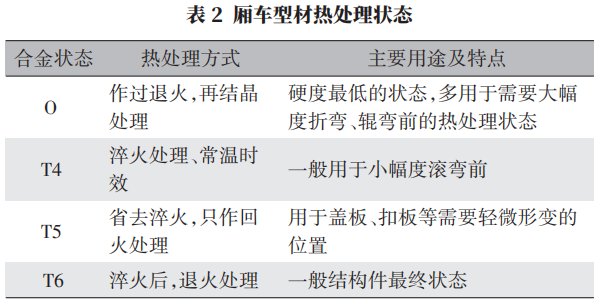

Aluminom alloy extrusion bụ a na-ekpo ọkụ akpụ usoro, na dum mmepụta usoro na-agụnye akpụ aluminom alloy n'okpuru atọ mkpakọ nrụgide. Enwere ike ịkọwa usoro mmepụta dum dịka ndị a: a. Aluminom na ihe ndị ọzọ na-agbaze ma tụba n'ime ihe ndị a chọrọ aluminom alloy billlets; b. A na-etinye billet ndị a na-ekpo ọkụ na-ekpo ọkụ n'ime ngwá ọrụ extrusion maka extrusion. N'okpuru ọrụ nke isi cylinder isi, a na-emepụta billet alloy aluminum n'ime profaịlụ achọrọ site na oghere nke ebu; c. Iji meziwanye akụrụngwa nke profaịlụ aluminom, a na-eme ọgwụgwọ ngwọta n'oge ma ọ bụ mgbe extrusion gasịrị, na-esote ọgwụgwọ ịka nká. Njirimara akụrụngwa mgbe ọgwụgwọ ịka nká na-adịgasị iche dịka ihe dị iche iche na usoro ịka nká si dị. Egosiri ọnọdụ ọgwụgwọ okpomọkụ nke profaịlụ ụdị igbe igbe na tebụl 2.

Aluminom alloy extruded ngwaahịa nwere ọtụtụ uru karịa ndị ọzọ akpụ ụzọ:

a. N'oge extrusion, metal extruded na-enweta nrụgide nrụgide ụzọ atọ siri ike ma dị mma na mpaghara nrụrụ karịa ịtụgharị na ịkpụgharị ya, ya mere ọ nwere ike igwu egwu plasticity nke metal a haziri. Enwere ike iji ya na-edozi ọla ndị siri ike na-agbanwe agbanwe nke a na-apụghị ịhazi site n'ịtụgharị ma ọ bụ akpụ akpụ ma nwee ike iji mee ihe dị mgbagwoju anya dị iche iche oghere ma ọ bụ ihe siri ike n'ofe akụkụ.

b. N'ihi na geometry nke profaịlụ aluminom nwere ike ịdị iche iche, ihe ndị mejupụtara ha nwere isi ike dị elu, nke nwere ike imeziwanye ihe siri ike nke ahụ ụgbọ ala, belata njirimara NVH ya, ma melite njirimara njikwa ike ụgbọ ala.

c. Ngwaahịa nwere arụmọrụ extrusion, mgbe emenyụchara na ịka nká, nwere ike ogologo ogologo (R, Raz) dị elu karịa ngwaahịa ejiri ụzọ ndị ọzọ edozi ya.

d. N'elu ngwaahịa mgbe extrusion nwere agba dị mma na nguzogide corrosion dị mma, na-ewepụ mkpa maka ọgwụgwọ elu mgbochi corrosion ọzọ.

e. Nhazi extrusion nwere nnukwu mgbanwe, obere ngwá ọrụ na ọnụ ahịa ebu, yana ọnụ ahịa mgbanwe dị ala.

f. N'ihi njikwa nke profaịlụ aluminom cross-sections, ogo nke ntinye ihe nwere ike ịba ụba, ọnụ ọgụgụ nke ihe nwere ike ibelata, na nhazi akụkụ dị iche iche nwere ike nweta nhazi ịgbado ọkụ.

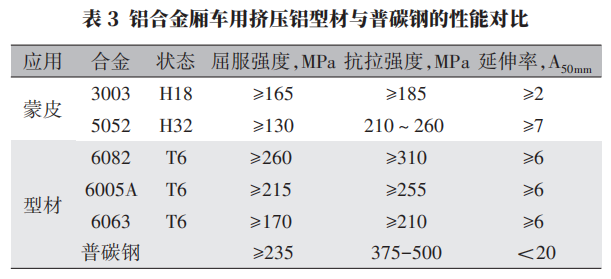

Ntụnyere arụmọrụ n'etiti profaịlụ aluminom extruded maka gwongworo ụdị igbe na ígwè carbon nkịtị ka egosiri na Tebụl 3.

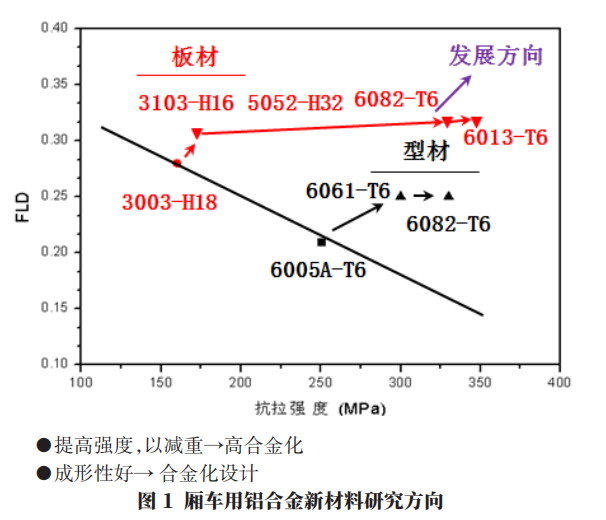

Ntuziaka mmepe ọzọ nke Profaịlụ Alloy Aluminom maka ụdị igbe igbe: Na-emewanye ike profaịlụ na ịkwalite arụmọrụ extrusion. E gosipụtara ntụzịaka nyocha nke ihe ọhụrụ maka profaịlụ alloy aluminum maka gwongworo ụdị igbe na eserese 1.

3.Aluminium Alloy Box Structure, Ike Nyocha, na nkwenye

3.1 Aluminium Alloy Box Structure Structure

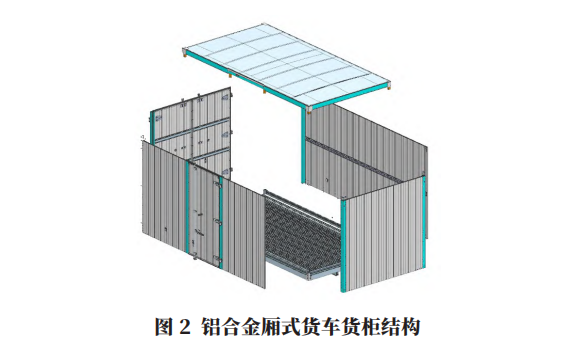

The igbe gwongworo akpa tumadi mejupụtara n'ihu panel nzukọ, ekpe na aka nri akụkụ panel nzukọ, n'azụ ụzọ n'akụkụ panel nzukọ, n'ala mgbakọ, ụlọ nzukọ, nakwa dị ka U-shaped bolts, n'akụkụ nche, n'azụ nche, apịtị flaps, na ndị ọzọ ngwa ejikọrọ na nke abụọ-klas chassis. Igbe ahụ obe obe, ogidi, ogwe akụkụ, na oghere ọnụ ụzọ bụ nke aluminom alloy extruded profaịlụ, ebe ala na elu ụlọ na-eme ka nke 5052 aluminum alloy flat plates. E gosipụtara nhazi nke igbe aluminom alloy na eserese 2.

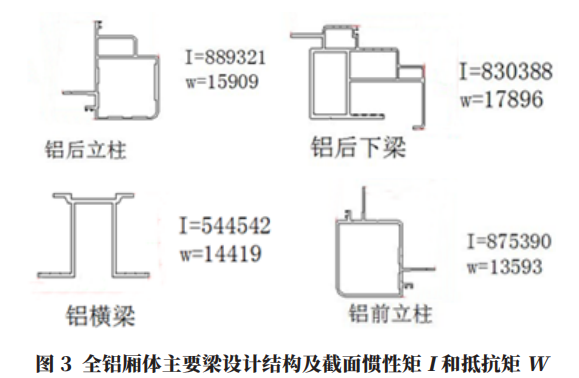

Iji usoro extrusion na-ekpo ọkụ nke 6 usoro aluminum alloy nwere ike ịmepụta akụkụ nke oghere oghere dị mgbagwoju anya, nhazi nke profaịlụ aluminom nwere akụkụ mgbagwoju anya nwere ike ịzọpụta ihe, izute ihe ndị a chọrọ nke ike ngwaahịa na isi ike, na izute ihe ndị a chọrọ nke njikọ n'etiti akụkụ dị iche iche. Ya mere, a na-egosi usoro nhazi nke isi na oge nkeji nke inertia I na oge imegide W na Figure 3.

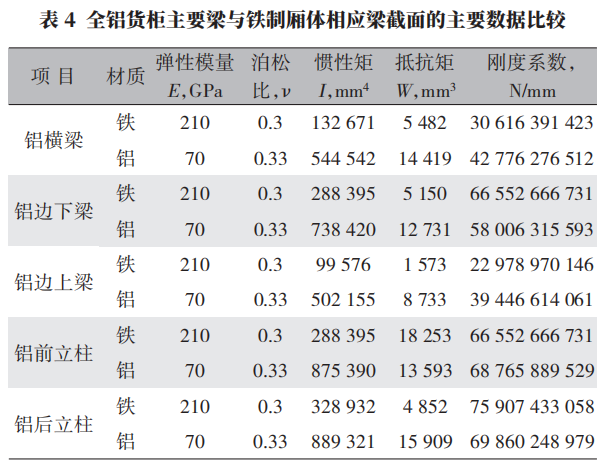

Ntụle nke isi data dị na Tebụl 4 na-egosi na oge akụkụ nke inertia na oge mgbochi nke profaịlụ aluminum a haziri dị mma karịa data kwekọrọ na profaịlụ beam nke ígwè. Ihe ndekọ ọnụ ọgụgụ isi ike dị ka nke profaịlụ beam nke ígwè arụnyere kwekọrọ, na ihe niile na-emezu nrụrụ chọrọ.

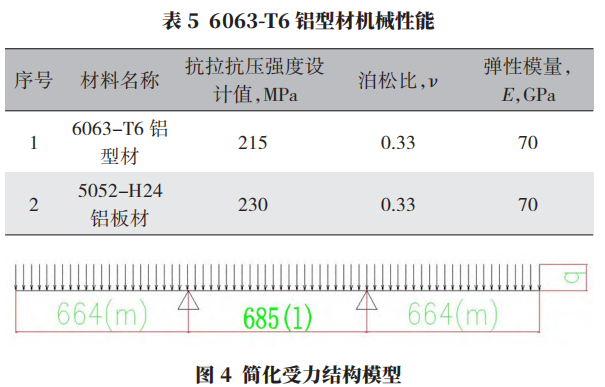

3.2 Mgbakọ nrụgide kachasị

Na-ewere isi ihe na-ebu ibu, crossbeam, dị ka ihe ahụ, a na-agbakọ nrụgide kachasị. Ibu ekwuru bụ 1.5 t, na crossbeam bụ nke 6063-T6 aluminum alloy profile with mechanical properties dị ka e gosiri na Tebụl 5. A na-eme ka ọkụ ahụ dị mfe dị ka ihe nhazi nke cantilever maka ngụkọ ike, dị ka egosiri na Figure 4.

Na-ewere 344mm span beam, a na-agbakọ ibu mkpakọ na beam dị ka F=3757 N dabere na 4.5t, nke bụ okpukpu atọ nke ọkọlọtọ static. q=F/L

ebe q bụ nrụgide dị n'ime nke ogwe n'okpuru ibu, N / mm; F bụ ibu na-ebu site na beam, gbakọọ dabere na ugboro 3 ọkọlọtọ ọkọlọtọ, nke bụ 4.5 t; L bụ ogologo osisi, mm.

Ya mere, nrụgide dị n'ime q bụ:

Usoro mgbako nrụgide bụ nke a:

Oge kachasị bụ:

Na-ewere uru zuru oke nke oge ahụ, M = 274283 N·mm, nrụgide kachasị σ = M / (1.05 × w) = 18.78 MPa, na uru nrụgide kachasị σ <215 MPa, nke na-emezu ihe ndị a chọrọ.

3.3 Njirimara njikọ nke ihe dị iche iche

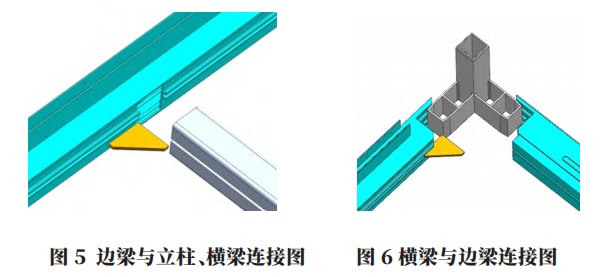

Aluminom alloy nwere adịghị mma ịgbado ọkụ Njirimara, na ya ịgbado ọkụ ebe ike bụ naanị 60% nke isi ihe ike. N'ihi mkpuchi nke akwa akwa nke Al2O3 na aluminum alloy elu, ebe mgbaze nke Al2O3 dị elu, ebe ebe mgbaze nke aluminom dị ala. Mgbe aluminom alloy na-welded, Al2O3 dị n'elu ga-agbaji ngwa ngwa ịrụ ịgbado ọkụ. N'otu oge ahụ, ihe fọdụrụ nke Al2O3 ga-anọgide na ngwọta aluminom alloy, na-emetụta usoro ihe ọkụkụ aluminom na ibelata ike nke ebe ịgbado ọkụ aluminom. Ya mere, mgbe ị na-emepụta akpa aluminom niile, a na-atụle njirimara ndị a nke ọma. Welding bụ isi n'usoro n'ọnọdu, na isi ihe na-ebu ibu na-ejikọta bolts. A na-egosi njikọ dị ka nrụnye na nhazi dovetail na foto 5 na 6.

Isi ihe owuwu nke igbe aluminom niile na-anabata ihe owuwu nwere oghere kwụ ọtọ, ogidi kwụ ọtọ, ogwe akụkụ, na oghere ọnụ na-ejikọta ibe ya. Enwere ebe njikọ anọ n'etiti oghere kwụ ọtọ na ogidi kwụ ọtọ. A na-etinye oghere njikọ ahụ na gaskets serrated ka ọ bụrụ ntupu na nsọtụ serrated nke oghere ahụ kwụ ọtọ, na-egbochi mwụda nke ọma. A na-ejikọta isi ihe nkuku asatọ ahụ site na ntinye isi nchara, edozi ya na bolts na rivets na-ekpuchi onwe ya, ma mesie ya ike site na 5mm triangular aluminum plates welded n'ime igbe iji wusie ọnọdụ nkuku ike n'ime. Ọdịdị dị n'èzí nke igbe ahụ enweghị welding ma ọ bụ ihe njikọ ekpughere, na-eme ka ọdịdị igbe ahụ dị n'ozuzu ya.

3.4 SE Synchronous Engineering Technology

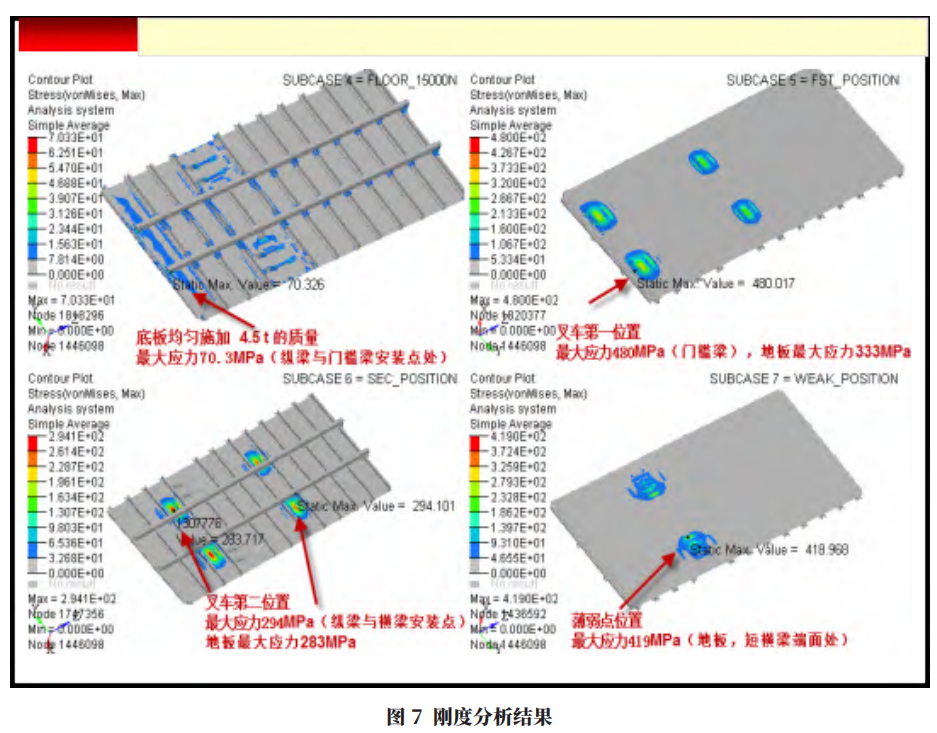

SE synchronous engineering technology na-eji na-edozi nsogbu kpatara nnukwu chịkọbara size deviations maka kenha components na igbe ahụ na ihe isi ike na-achọta ihe na-akpata gaps na flatness ọdịda. Site na nyocha CAE (lee eserese 7-8), a na-eme nyocha ntụnyere na igbe igbe e mere ígwè iji lelee ike zuru oke na isi ike nke igbe ahụ, chọta ebe adịghị ike, ma mee ihe iji kwalite na melite atụmatụ nhazi nke ọma.

4.Lightweighting Mmetụta nke Aluminom Alloy Box Truck

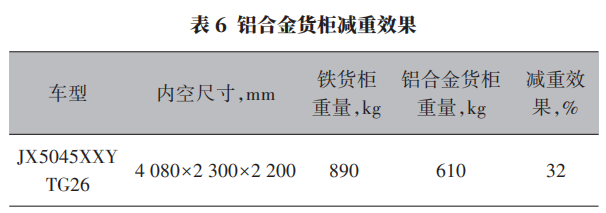

Na mgbakwunye na ahụ igbe, aluminom alloys nwere ike iji dochie ígwè maka dị iche iche akụkụ nke igbe ụdị igbe igbe, dị ka apịtị, n'azụ nche, n'akụkụ nche, ụzọ latches, ọnụ ụzọ hinges, na n'azụ apron n'akụkụ, nweta a arọ Mbelata 30% ka 40% maka ibu ngalaba. The arọ Mbelata mmetụta maka ihe efu 4080mm × 2300mm × 2200mm ibu akpa e gosiri na Isiokwu 6. Nke a fundamentally solves nsogbu nke oke ibu, na-abụghị nnabata na ọkwa, na usoro ihe ize ndụ nke omenala ígwè mere ibu compartments.

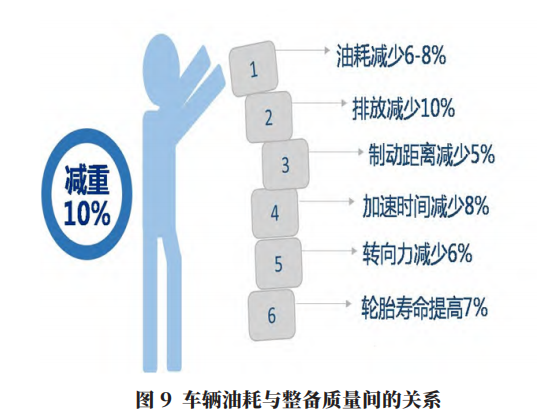

Site n'iji ígwè aluminom dochie ígwè ọdịnala na ihe ndị na-emepụta ụgbọ ala, ọ bụghị nanị na enwere ike nweta mmetụta dị arọ nke ọma, ma ọ nwekwara ike inye aka na nchekwa mmanụ, mbelata ikuku, na ịrụ ọrụ ụgbọ ala ka mma. Ka ọ dị ugbu a, enwere echiche dị iche iche na ntinye aka nke fechaa iji chekwaa ego mmanụ ọkụ. E gosipụtara nsonaazụ nyocha nke International Aluminum Institute na eserese 9. Mbelata 10% ọ bụla na ịdị arọ ụgbọ ala nwere ike belata oriri mmanụ site na 6% ruo 8%. Dabere na ọnụ ọgụgụ ụlọ, ibelata ibu nke ụgbọ ala ndị njem ọ bụla site na 100 n'arọ nwere ike belata oriri mmanụ site na 0.4 L / 100 km. Ntinye aka nke ịdị arọ na-echekwa mmanụ ọkụ sitere na nsonaazụ enwetara site na ụzọ nyocha dị iche iche, yabụ enwere mgbanwe ụfọdụ. Agbanyeghị, ịfefe ụgbọ ala nwere mmetụta dị ukwuu na ibelata oriri mmanụ.

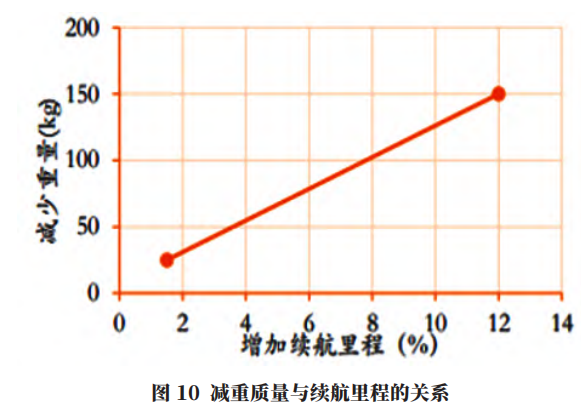

Maka ụgbọ ala eletrik, mmetụta dị arọ na-apụta ọbụna karịa. Ugbu a, njupụta ike nke batrị ike ụgbọ ala eletrik dị nnọọ iche na nke ụgbọ ala mmiri mmiri ọdịnala. Ibu nke sistemu ike (gụnyere batrị) nke ụgbọ ala eletrik na-abụkarị 20% ruo 30% nke mkpokọta ibu ụgbọ ala. N'otu oge ahụ, ịgbaji n'ime obere ọrụ batrị bụ ihe ịma aka zuru ụwa ọnụ. Tupu enwee nnukwu ọganihu na teknụzụ batrị na-arụ ọrụ dị elu, ịfefe ibu bụ ụzọ dị irè isi melite ụdị njem ụgbọ ala eletrik. Maka mbelata 100kg ọ bụla nke ịdị arọ, ọnụọgụ ụgbọ ala eletrik nwere ike ịbawanye site na 6% ruo 11% (mmekọrịta dị n'etiti mbelata ibu na oke ịkwọ ụgbọ mmiri ka egosiri na foto 10). Ka ọ dị ugbu a, ụgbọ ala eletrik dị ọcha na-akwọ ụgbọ mmiri enweghị ike gboo mkpa nke ọtụtụ ndị mmadụ, mana ibelata ibu site na obere ego nwere ike melite oke njem ụgbọ mmiri, na-ebelata nchekasị nke ukwuu na imeziwanye ahụmịhe onye ọrụ.

5.Mkpebi

Na mgbakwunye na usoro aluminom niile nke gwongworo igbe alloy aluminom ewebata n'isiokwu a, e nwere ụdị igbe igbe dị iche iche, dị ka ogwe osisi alumini mmanụ aṅụ, efere alumini, okpokolo agba + aluminom skins, na ngwongwo ngwongwo ígwè-aluminom ngwakọ. Ha nwere uru nke ịdị arọ dị arọ, ike dị elu dị elu, na ezigbo nkwụsị nke corrosion, na-adịghị achọ electrophoretic agba maka nchebe corrosion, ibelata mmetụta gburugburu ebe obibi nke electrophoretic agba. Gọọmenti igbe aluminom alloy na-edozi nsogbu nke oke ibu, enweghị nnabata ọkwa, yana ihe egwu na-achịkwa nke ngalaba ibu ígwè emere.

Extrusion bụ usoro nhazi dị mkpa maka aluminom alloys, na profaịlụ aluminom nwere ihe eji arụ ọrụ nke ọma, yabụ isi ike nke akụkụ ahụ dị oke elu. N'ihi akụkụ nke na-agbanwe agbanwe, aluminom alloys nwere ike nweta nchikota nke ọtụtụ ọrụ akụrụngwa, na-eme ka ọ bụrụ ihe dị mma maka ọkụ ọkụ ụgbọ ala. Otú ọ dị, ngwa n'ebe nile nke aluminom alloys na-eche ihe ịma aka ndị dị ka ezughị ezu imewe ike maka aluminum alloy ibu ngalaba, akpụ na ịgbado ọkụ okwu, na elu mmepe na nkwalite ụgwọ maka ọhụrụ ngwaahịa. Isi ihe kpatara ya bụ na aluminom alloy na-akwụ ụgwọ karịa nchara tupu ecology recycling nke aluminum alloys tozuo oke.

Na mmechi, ngwa ngwa nke aluminom alloys n'ime ụgbọ ala ga-abawanye ụba, ojiji ha ga-aga n'ihu na-abawanye. N'ime usoro dị ugbu a nke ịzọpụta ike, mbelata ikuku, na mmepe nke ụlọ ọrụ ụgbọ ala ike ọhụrụ, na nghọta miri emi nke akụrụngwa alloy aluminom na ngwọta dị mma maka nsogbu ngwa aluminom alloy, a ga-eji ihe extrusion aluminom mee ihe n'ọtụtụ ebe na-ebufe ụgbọ ala.

May Jiang deziri site na MAT Aluminum

Oge nzipu: Jan-12-2024