Ịdị arọ nke ụgbọ ala bụ otu ebumnuche nke ụlọ ọrụ ụgbọ ala zuru ụwa ọnụ. Ịbawanye iji ihe aluminom alloy eme ihe na akụrụngwa ụgbọ ala bụ ntụzịaka nke mmepe maka ụgbọ ala ọhụrụ nke oge a. 6082 aluminum alloy bụ ihe na-ekpo ọkụ na-agwọ ọrịa, aluminom alloy siri ike na ike dị oke oke, nhazi dị mma, weldability, ike ọgwụgwụ, na nguzogide corrosion. Nke a alloy nwere ike extruded n'ime ọkpọkọ, mkpara, na profaịlụ, na ọ na-ọtụtụ ebe na-eji ụgbọ ala components, welded structural akụkụ, njem, na ihe owuwu ụlọ ọrụ.

Ugbu a, enwere ntakịrị nyocha na 6082 aluminum alloy maka ojiji n'ime ụgbọ ala ume ọhụrụ na China. Ya mere, nyocha nnwale a na-enyocha mmetụta nke 6082 aluminom alloy element content range, usoro extrusion usoro, ụzọ nkwụsị, wdg, na arụmọrụ profaịlụ alloy na microstructure. Ọmụmụ ihe a na-achọ ịkwalite ihe mejupụtara alloy na usoro nhazi iji mepụta ihe 6082 aluminum alloy dabara maka ụgbọ ala ike ọhụrụ.

1. Ngwa ule na ụzọ

Usoro nnwale: Alloy mejupụtara ruru – Ingot agbaze – Ingot homogenization – Ingot sawing n’ime billets – Extrusion nke profaịlụ – In-line quenching nke profaịlụ – Artificial ịka nká – Nkwadebe nke ụdị ule.

1.1 Nkwadebe Ingot

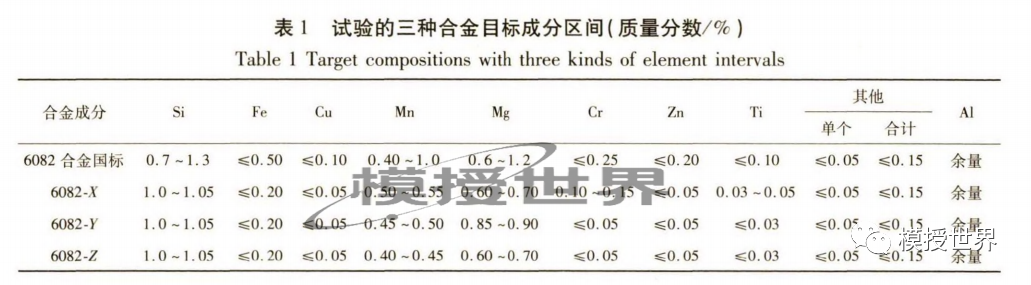

N'ime mba ụwa nke 6082 aluminom alloy compound, ahọpụtara ihe mejupụtara atọ nwere oke njikwa dị warara, nke akpọrọ 6082-/6082″, 6082-Z, nwere otu ọdịnaya Si element. Mg mmewere ọdịnaya, y > z; Mn ọdịnaya, x > y > z; Cr, Ti mmewere ọdịnaya, x> y = z. A na-egosi ụkpụrụ ebumnuche ihe mejupụtara alloy akọwapụtara na tebụl 1. A na-eme nkedo ingot site na iji usoro nkedo mmiri na-aga n'ihu na-aga n'ihu, na-esote ọgwụgwọ homogenization. All ingots atọ bụ homogenized site na iji ụlọ ọrụ na-eguzobe usoro na 560°C maka 2 awa na mmiri alụlụ jụrụ.

1.2 Mwepu nke profaịlụ

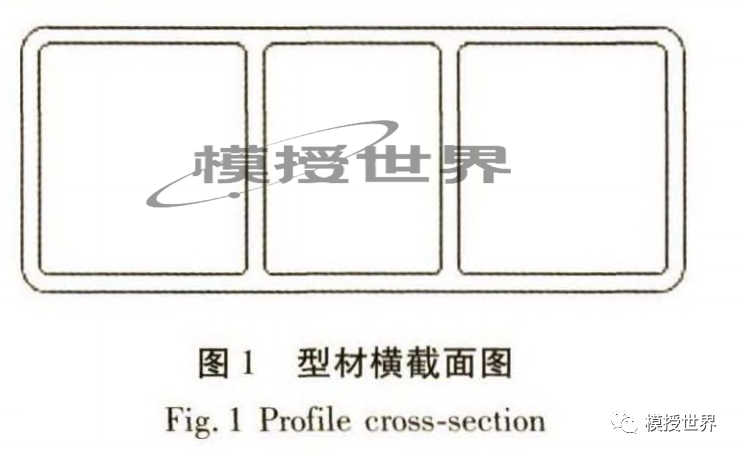

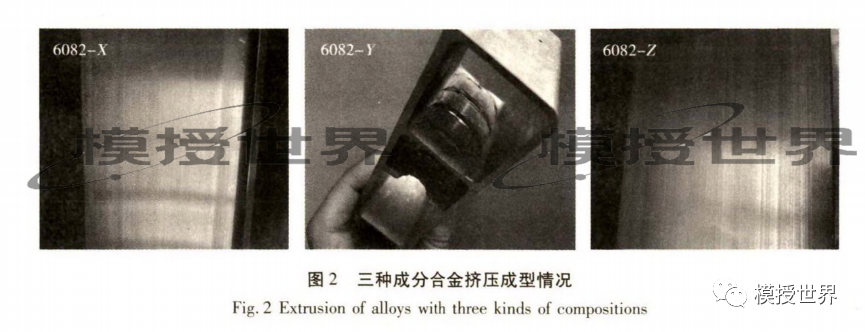

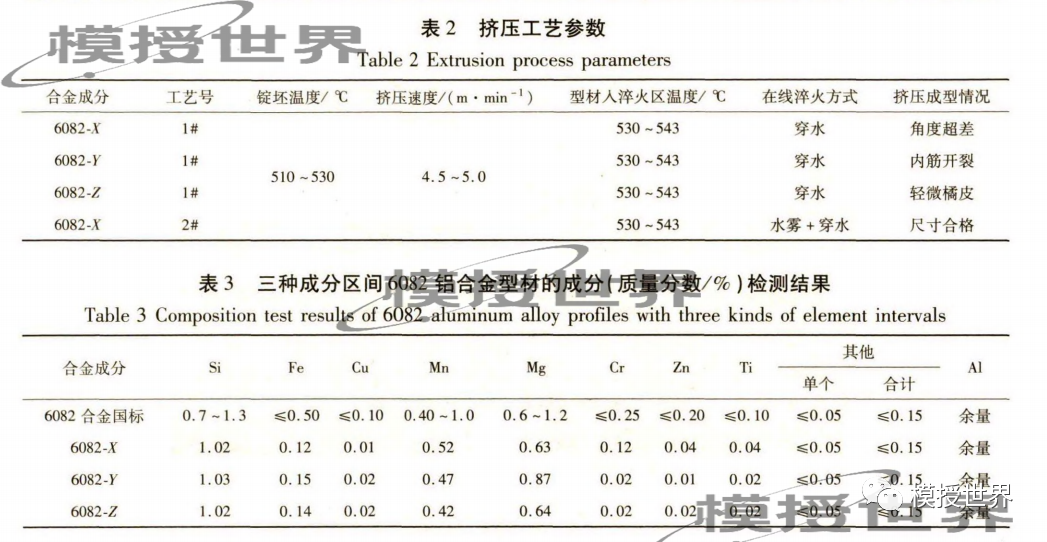

Emeziri usoro extrusion nke ọma maka ikpo ọkụ billet yana ọnụego jụrụ oyi. E gosipụtara akụkụ obe nke profaịlụ extruded na Figure 1. A na-egosi usoro nhazi nke extrusion na tebụl 2. E gosipụtara ọnọdụ nhazi nke profaịlụ extruded na Figure 2.

2.Nchọpụta ule na nyocha

Ihe mejupụtara kemịkalụ akọwapụtara nke profaịlụ alloy 6082 aluminom dị n'ime usoro atọ a ka ekpebisiri ike site na iji spectrometer Switzerland ARL kpọmkwem, dị ka egosiri na Tebụl 3.

2.1 Nnwale arụmọrụ

N'iji tụnyere, a na-enyocha arụmọrụ nke profaịlụ alloy dị iche iche mejupụtara atọ nwere ụzọ dị iche iche na-emenyụ ọkụ, ihe ndị yiri extrusion, na usoro ịka nká.

2.1.1 Mechanical Arụmọrụ

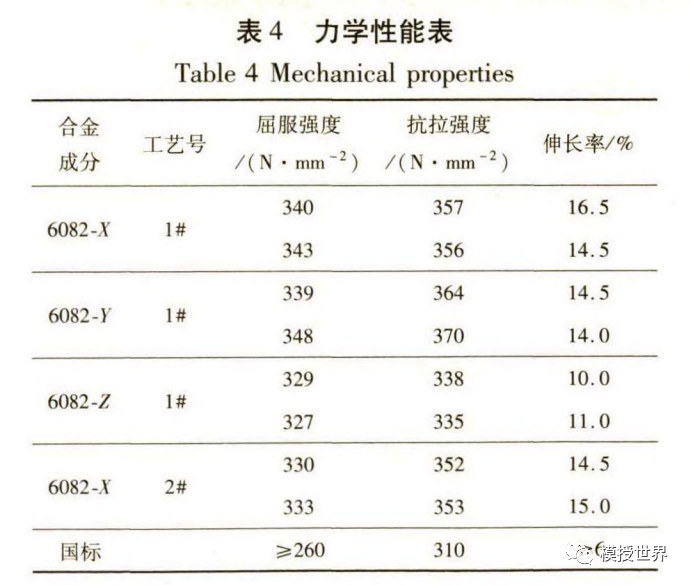

Mgbe emechara agadi na 175 Celsius C maka awa 8, a na-ewepụta ihe atụ ọkọlọtọ site na ntụzịaka nke extrusion nke profaịlụ maka nnwale tensile site na iji igwe nnwale elektrọn nke Shimadzu AG-X100. E gosipụtara ịrụ ọrụ igwe mgbe ịka nká na-arụ ọrụ maka nhazi dị iche iche na ụzọ nkwụsịtụ na Tebụl 4.

Site na Tebụl 4, enwere ike ịhụ na arụmọrụ arụ ọrụ nke profaịlụ niile karịrị ụkpụrụ ọkọlọtọ mba. Profaịlụ emepụtara site na 6082-Z alloy billlets nwere elongation dị ala mgbe agbajichara. Profaịlụ emepụtara site na 6082-7 alloy billlets nwere ọrụ igwe kachasị elu. Profaịlụ alloy 6082-X, nwere ụzọ ngwọta siri ike dị iche iche, gosipụtara arụmọrụ dị elu site na iji ụzọ nkwụsị ngwa ngwa jụrụ oyi.

2.1.2 Nnwale arụmọrụ na-ehulata

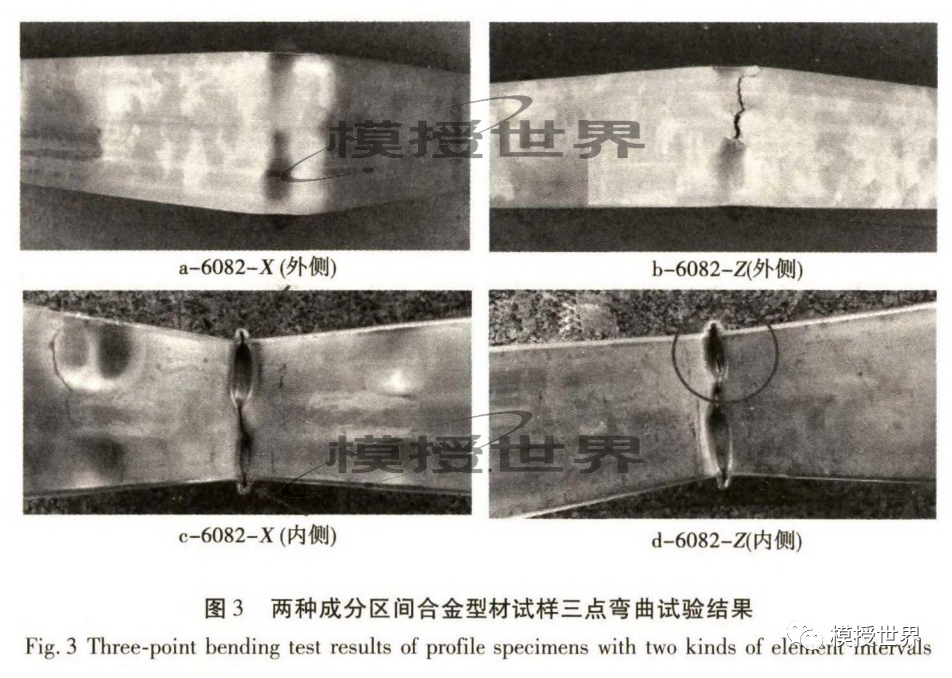

N'iji igwe ule eletrọnịkị nke eluigwe na ala, a na-eduzi ule na-ehulata isi atọ na ihe nlele, na-egosipụtakwa nsonaazụ na-ehulata na Figure 3. Ihe osise 3 na-egosi na ngwaahịa ndị sitere na 6082-Z alloy billlets nwere nnukwu peel oroma dị n'elu ma na-agbawa n'azụ ihe nlele ahụ gbagoro agbagọ. Ngwaahịa ndị sitere na 6082-X alloy billlets nwere arụmọrụ na-ehulata ka mma, ebe dị larịị na-enweghị peel oroma, yana naanị obere mgbawa n'ọnọdụ ọnọdụ geometric ejedebere n'azụ ihe nlele agbagọ.

2.1.3 Nleba anya dị elu

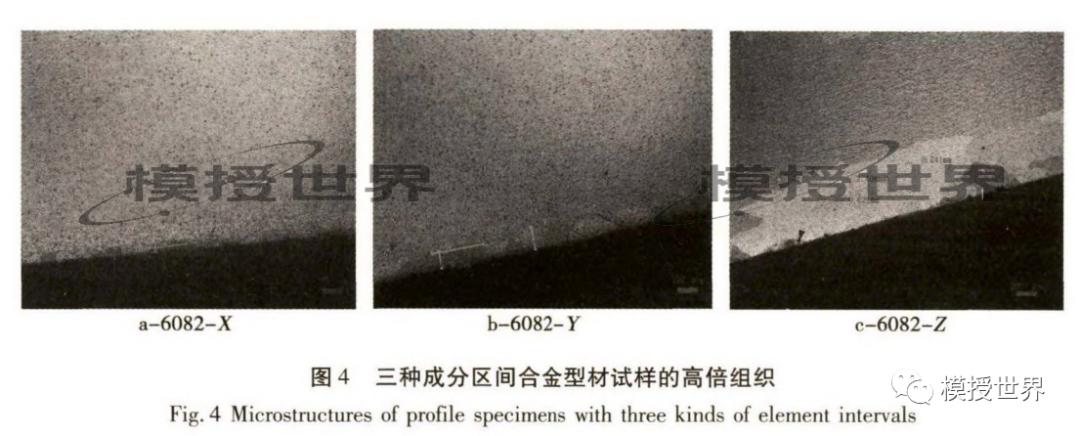

Ahụrụ nlele n'okpuru microscope anya Carl Zeiss AX10 maka nyocha microstructure. A na-egosi nsonaazụ nyocha microstructure maka profaịlụ alloy nke atọ mejupụtara na eserese 4. Ihe osise 4 na-egosi na nha ọka nke ngwaahịa ndị sitere na mkpanaka 6082-X na 6082-K alloy billet yiri nke ahụ, nke nwere obere ọka ka mma na 6082-X alloy ma e jiri ya tụnyere 6082-y alloy. Ngwaahịa ndị sitere na 6082-Z alloy billlets nwere oke ọka buru ibu na akwa cortex buru ibu, nke na-ebute ngwa ngwa n'elu peel oroma yana ike gwụ njikọ nke ime ụlọ.

2.2 Nyochaa nsonaazụ

Dabere na nsonaazụ ule a dị n'elu, enwere ike ikwubi na nhazi nke ụdị ihe mejupụtara alloy na-emetụta nke ọma microstructure, arụmọrụ, na nhazi profaịlụ nke extruded. Ọdịnaya Mg na-abawanye na-ebelata plasticity alloy ma na-eduga n'ichebe mgbawa n'oge extrusion. Ọdịnaya Mn, Cr, na Ti dị elu nwere mmetụta dị mma n'ịnụcha microstructure, nke n'aka nke ya na-emetụta ịdịmma elu elu, ịrụ ọrụ ịgbagọ, na arụmọrụ n'ozuzu ya.

3.Mkpebi

Mg element na-emetụta nke ọma n'ibu ọrụ nke 6082 aluminum alloy. Ọdịnaya Mg na-abawanye na-ebelata plasticity alloy ma na-eduga n'ichebe mgbawa n'oge extrusion.

Mn, Cr, na Ti na-enwe mmetụta dị mma na nhazigharị microstructure, na-eduga n'ịdị mma elu elu yana ịgbagọ ọrụ nke ngwaahịa ndị extruded.

Mmetụta dị jụụ na-ekpo ọkụ dị iche iche nwere mmetụta pụtara ìhè na arụmọrụ nke profaịlụ alloy 6082 aluminum. Maka iji ụgbọ ala, ịnakwere usoro nkwụsị nke alụlụ mmiri na-esote nke mmiri na-agbaju mmiri na-enye ọrụ arụ ọrụ ka mma ma na-eme ka profaịlụ 'ụdị na nha anya ziri ezi.

May Jiang deziri site na MAT Aluminum

Oge nzipu: Mar-26-2024