Ọ bụrụ na ihe eji arụ ọrụ nke extrusions adịghị ka a tụrụ anya ya, a na-elekwasịkarị anya na nhazi mbụ nke billet ma ọ bụ ọnọdụ extrusion / ịka nká. Ọ bụ mmadụ ole na ole na-ajụ ma homogenization n'onwe ya nwere ike ịbụ okwu. N'ezie, usoro homogenization dị oké mkpa maka ịmepụta extrusions dị elu. Ọdịda ịchịkwa nke ọma nzọụkwụ homogenization nwere ike iduga:

●Mbara mgbali elu

●Nkwarụ ndị ọzọ

● Striak textures mgbe anodizing

●Obere extrusion ọsọ

● Ngwá ọrụ na-adịghị mma

The homogenization ogbo nwere isi ihe abụọ bụ isi: Nnụcha ígwè-nwere intermetallic ogige, na redistributing magnesium (Mg) na silicon (Si). Site n'inyocha microstructure nke billet tupu na mgbe homogenization, onye nwere ike ịkọ ma billet ọ ga-arụ ọrụ nke ọma n'oge extrusion.

Mmetụta nke Billet Homogenization na Hardening

Na extrusion 6XXX, ike na-abịa site na usoro Mg- na Si-ọgaranya emebere n'oge ịka nká. Ikike ịmepụta usoro ndị a na-adabere n'itinye ihe ndị ahụ na ngwọta siri ike tupu ịka nká amalite. Ka Mg na Si mechaa bụrụ akụkụ nke ngwọta siri ike, ígwè ahụ ga-emenyụ ngwa ngwa site n'elu 530 Celsius. N'ebe okpomọkụ dị n'elu ebe a, Mg na Si na-agbaze n'ime aluminom. Otú ọ dị, n'oge extrusion, metal na-anọgide n'elu okpomọkụ a maka obere oge. Iji hụ na mgwakota agwa na Si niile gbazere, irighiri ihe mg na Si kwesịrị ịdị ntakịrị. N'ụzọ dị mwute, n'oge nkedo, Mg na Si na-ebuli dị ka nnukwu Mg₂Si blocks (Fig. 1a).

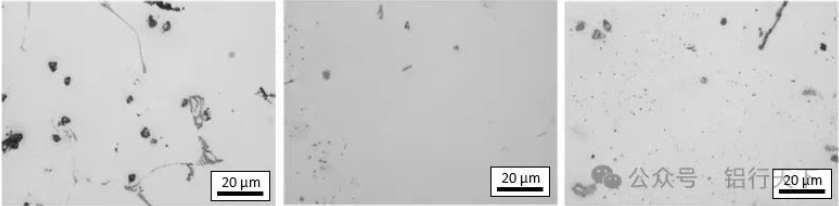

A-ahụkarị homogenization okirikiri maka 6060 billets bụ 560 Celsius C maka 2 awa. N'oge usoro a, ebe ọ bụ na billet na-anọ n'elu 530 Celsius ruo ogologo oge, Mg₂Si na-agbaze. Mgbe ọ dị jụụ, ọ na-atụgharịghachi na nkesa kachasị mma (Fig 1c). Ọ bụrụ na okpomọkụ homogenization adịghị elu, ma ọ bụ oge dị mkpụmkpụ, ụfọdụ nnukwu Mg₂Si ga-adị. Mgbe nke a mere, ihe ngwọta siri ike mgbe extrusion nwere obere Mg na Si, na-eme ka ọ ghara ikwe omume ịmepụta nnukwu njupụta nke ihe siri ike - na-eduga n'ịbelata akụrụngwa.

Fig. 1. Ngwa anya micrographs nke na-egbu maramara na 2% HF-etched 6060 billets: (a) dị ka nkedo, (b) akụkụ ụfọdụ homogenized, (c) zuru ezu homogenized.

Ọrụ nke Homogenization na Intermetallic nwere Iron

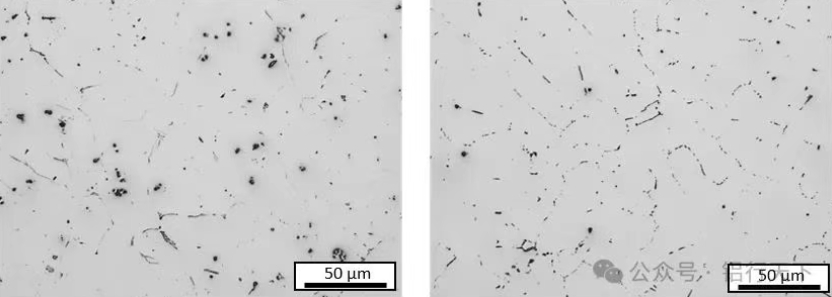

Ígwè (Fe) na-enwe mmetụta dị ukwuu na mgbaji siri ike karịa ike. Na alloys 6XXX, usoro Fe na-etolite β-phase (Al₅(FeMn) Si ma ọ bụ Al₈.₉(FeMn)₂Si₂) n'oge nkedo. Usoro ndị a buru ibu, akụkụ, ma na-egbochi extrusion (nke pụtara na fig. 2a). N'oge homogenization, ihe ndị dị arọ (Fe, Mn, wdg) na-agbasa, na nnukwu akụkụ akụkụ na-adị ntakịrị na gburugburu (Fig 2b).

Site na onyonyo anya naanị, ọ na-esiri ike ịmata ọdịiche dị n'ụdị dị iche iche, ọ gaghị ekwe omume ịkọwapụta ha nke ọma. Na Innoval, anyị na-akọwapụta homogenization billet site na iji ụzọ nchọpụta njirimara na nhazi ọkwa (FDC), nke na-enye uru %α maka billet. Nke a na-enyere anyị aka inyocha àgwà nke homogenization.

Fig. 2. Optical micrographs of billlets (a) tupu na (b) mgbe homogenization.

Usoro nchọpụta na nhazi ọkwa (FDC).

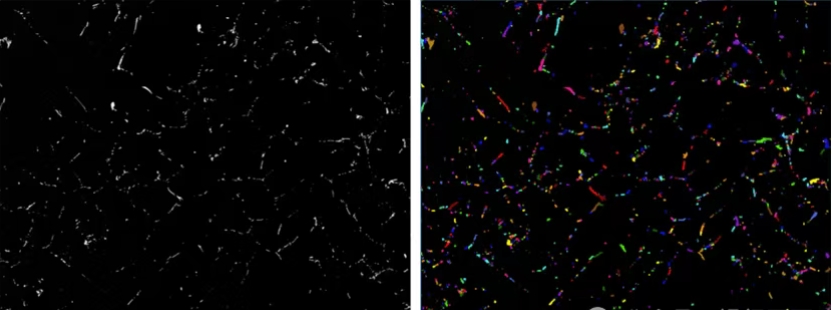

Fig. 3a na-egosi nlele a na-egbu maramara nke a na-enyocha site na nyocha eletrọnịkị microscopy (SEM). A na-etinyekwa usoro nbata isi awọ iji kewapụ ma chọpụta intermetallics, nke pụtara na-acha ọcha na Fig. 3b. Usoro a na-enye ohere nyocha nke mpaghara ruo 1 mm², nke pụtara na enwere ike nyochaa ihe karịrị 1000 n'otu n'otu n'otu oge.

Fig. 3. (a) Onyinyo eletrọn gbasasịa azụ nke homogenized 6060 billet, (b) chọpụtara njirimara onye ọ bụla sitere na (a).

Ihe mejupụtara

Ejiri sistemụ Innoval nwere ihe nyocha X-ray nke Oxford Instruments Xplore 30 (EDX). Nke a na-enye ohere nchịkọta EDX ngwa ngwa akpaka site na ebe ọ bụla achọpụtara. Site na ụdịdị ndị a, enwere ike ikpebi ihe mejupụtara ya, yana oke Fe: Si ruru.

Dabere na ọdịnaya Mn ma ọ bụ Cr nke alloy, enwere ike itinye ihe ndị ọzọ dị arọ. Maka ụfọdụ alloys 6XXX (mgbe ụfọdụ nwere nnukwu Mn), a na-eji (Fe+Mn): Si ratio dị ka ntụnye aka. Enwere ike iji nha ndị a tụnyere nke ihe intermetallic nwere Fe nwere ama ama.

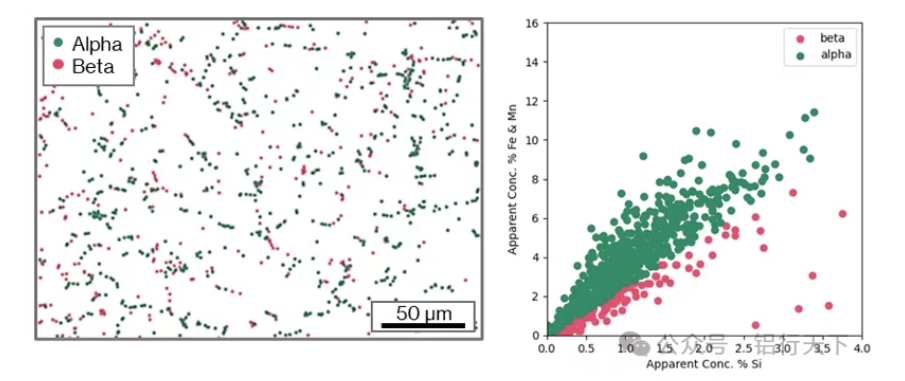

β-phase (Al₅ (FeMn) Si ma ọ bụ Al₈.₉ (FeMn)₂Si₂): (Fe+Mn): Si ratio ≈ 2. α-phase (Al₁₂(FeMn)₃Si ma ọ bụ Al₈.₃(FeMn):–6, dabere na mejupụtara. Akụrụngwa omenala anyị na-enye anyị ohere ịtọ ọnụ ụzọ ma kewaa ihe ọ bụla dị ka α ma ọ bụ β, wee mapụta ọnọdụ ha n'ime microstructure (Fig 4). Nke a na-enye ihe dị ka pasenti nke α gbanwere na billet a na-emekọ ihe.

Ihe oyiyi 4. (a) Map na-egosi α- na β-nkewa ụmụ irighiri ihe, (b) nhazi nke (Fe+Mn): Si ratios.

Ihe Data nwere ike ịgwa anyị

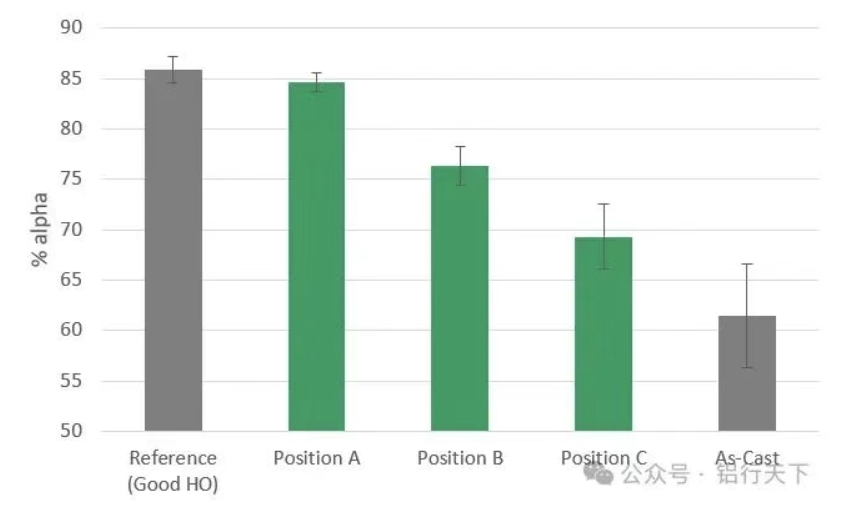

Fig. 5 na-egosi ihe atụ nke otu esi eji ozi a. N'okwu a, nsonaazụ ya na-egosi ikpo ọkụ na-abụghị otu n'ime otu ọkụ ọkụ, ma ọ bụ ikekwe na ọnọdụ okpomọkụ adịghị erute. Iji nyochaa ikpe ndị dị otú ahụ nke ọma, a chọrọ ma billet ule na akwụkwọ ntụaka nke àgwà amaara. Enweghị ihe ndị a, enweghị ike ịmepụta oke% α tụrụ anya maka ngwakọta alloy ahụ.

Fig. 5. Tụnyere %α na ngalaba dị iche iche nke ọkụ homogenization na-adịghị mma.

Oge nzipu: Ọgọst-30-2025