Emere nyocha sara mbara na mgbakwunye nke ihe ndị na-adịghị ahụkebe ụwa (REEs) na 7xxx, 5xxx, na 2xxx usoro aluminum alloys, na-egosi mmetụta pụtara ìhè. Karịsịa, 7xxx usoro aluminum alloys, nke nwere ọtụtụ ihe na-emepụta ihe, na-enwekarị ikewapụ oke n'oge agbaze na nkedo, na-eduga n'ịmepụta nnukwu usoro eutectic. Nke a na-ebelata ike na nguzogide corrosion, na-emebi ọrụ niile nke alloy. Mwekota nke ihe ndị na-adịghị ahụkebe n'ụwa n'ime alloys aluminom nke ukwuu nwere ike ime ka ọka dị mma, gbochie nkewa, na sachaa matriks ahụ, si otú ahụ na-emeziwanye microstructure na ihe niile.

N'oge na-adịbeghị anya, ụdị ihe nchacha ọka superplastic enwetawo nlebara anya. Ndị na-anụcha ihe ndị a na-erigbu ihe ndị na-adịghị ahụkebe nke ụwa dị ka La na Ce iji kwalite adịghị ike nke ọka na oke ala. Ọ bụghị nanị na nke a na-anụcha ọka ma na-akwalite otu ụdị mgbasa nke precipitates, na-egbochi recrystallization, ma na-eme ka alloy ductility dịkwuo mma, n'ikpeazụ na-abawanye mmepụta na usoro extrusion.

Na usoro 7xxx aluminum alloys, a na-agbakwunye ihe ndị na-adịghị ahụkebe ụwa n'ụzọ atọ:

1.Rare ụwa ọcha naanị;

2.Combination nke Zr na obere ụwa ọcha;

3. Ngwakọta nke Zr, Cr, na ihe ndị dị ụkọ n'ụwa.

A na-achịkwakarị ọdịnaya nke ihe ndị dị ụkọ n'ụwa n'ime 0.1-0.5 wt.

Usoro nke ihe ndị dị ụkọ n'ụwa

Ihe ndị na-adịghị ahụkebe dị ka La, Ce, Sc, Er, Gd, na Y na-enye aka na aluminom alloys site na ọtụtụ usoro:

Nnụcha ọka: Ihe ndị na-adịghị ahụkebe n'ụwa na-etolite ebili mmiri na-ekesa n'otu n'otu na-arụ ọrụ dị ka saịtị nucleation dị iche iche, na-agbanwe ihe owuwu dendritic ka ọ bụrụ ọka dị mma dabara adaba, nke na-eme ka ike na ductility dịkwuo mma.

Mbelata nkewa: N'oge agbaze na nkwụsi ike, ihe ndị na-adịghị ahụkebe nke ụwa na-akwalite nkesa otu ihe, belata nhazi eutectic, na ịbawanye njupụta matriks.

Matrix dị ọcha: Y, La, na Ce nwere ike meghachi omume na adịghị ọcha na agbaze (O, H, N, S) iji mepụta ogige kwụsiri ike, na-ebelata ọdịnaya gas na ntinye, nke na-eme ka ogo alloy dịkwuo mma.

Mgbanwe nke omume recrystallization: Ụfọdụ ihe ndị na-adịghị ahụkebe n'ụwa nwere ike tụnye ọka na oke ala, na-egbochi ịkwagharị ebe na ịkwaga oke oke ọka. Nke a na-egbu oge recrystallization ma na-echekwa ezigbo ihe owuwu subgrain n'oge nhazi okpomọkụ, na-emeziwanye ike na nguzogide corrosion.

Ihe ndị bụ isi na-adịghị ahụkebe na mmetụta ha

Scandium (Sc)

Sc nwere radius atọ kacha nta n'etiti ihe ndị dị ụkọ n'ụwa ma bụrụkwa ọla ngbanwe. Ọ na-arụ ọrụ nke ọma n'ịkwalite njirimara nke alloys aluminum deformed.

Na aluminom alloys, Sc precipitate dị ka coherent Al₃Sc, na-abawanye okpomọkụ recrystallization na-egbochi ịkpakọba ọka.

Mgbe ejikọtara ya na Zr, oke okpomọkụ kwụsiri ike Al₃ (Sc, Zr) irighiri ihe na-etolite, na-akwalite mkpụrụ ọka dị mma ma na-egbochi mmegharị mmegharị na mbugharị oke oke ọka. Nke a na-eme ka ike dịkwuo mma, nkwụsị ike ọgwụgwụ, na ịrụ ọrụ nrụgide-corrosion.

Oke Sc nwere ike iduga irighiri ihe Al₃ (Sc, Zr), na-ebelata ikike recrystallization, ike, na ductility.

Erbium (Ea)

Er na-eme otu ihe ahụ na Sc mana ọ na-eri ọnụ karịa.

Na usoro alloys 7xxx, mgbakwunye Er kwesịrị ekwesị na-emecha ọka, na-egbochi mmegharị mgbanwe na mbugharị ókèala ọka, na-ebelata recrystallization, ma welie ike.

Mgbe agbakwunyere ya na Zr, ụmụ irighiri ihe Al₃ (Er,Zr) na-etolite, bụ nke kwụsiri ike karịa Al₃Er naanị, na-enye mbelata recrystallization ka mma.

Oke Er nwere ike iwepụta usoro Al₈Cu₄er, na-ebelata ma ike na ductility.

Gadolinium (Gd)

Mgbakwunye Gd na-agafeghị oke na-emecha ọka, na-abawanye ike na ductility, ma kwalite solubility nke Zn, Mg, na Cu na matriks.

Usoro Al₃(Gd,Zr) nke si na ya pụta na-atụnye mwepu na oke ala, na-egbochi recrystallization. Ihe nkiri na-arụ ọrụ na-etolitekwa n'elu ọka, na-egbochi uto ọka.

Gd karịrị akarị nwere ike ime ka ịhịa aka n'ahụ na-emebi emebi.

Lanthanum (La), Cerium (Ce), na Yttrium (Y)

La na-anụcha ọka, na-ebelata ikuku oxygen, ma mepụta ihe nkiri na-arụ ọrụ n'elu ọka iji gbochie uto.

La na Ce na-akwalite mpaghara GP na η′ nke mmiri ozuzo, na-eme ka ike matriks na-eguzogide corrosion.

Y na-asachapụ matriks ahụ, na-egbochi mgbasa nke isi ihe na-eme ka ọ bụrụ ihe ngwọta siri ike, na-akwalite nucleation, ma na-ebelata esemokwu nwere ike n'etiti oke ọka na ime ụlọ, na-eme ka nkwụsị nke corrosion dịkwuo elu.

Oke La, Ce, ma ọ bụ Y nwere ike iduga na ogige mgbochi nke na-ebelata ductility na ike.

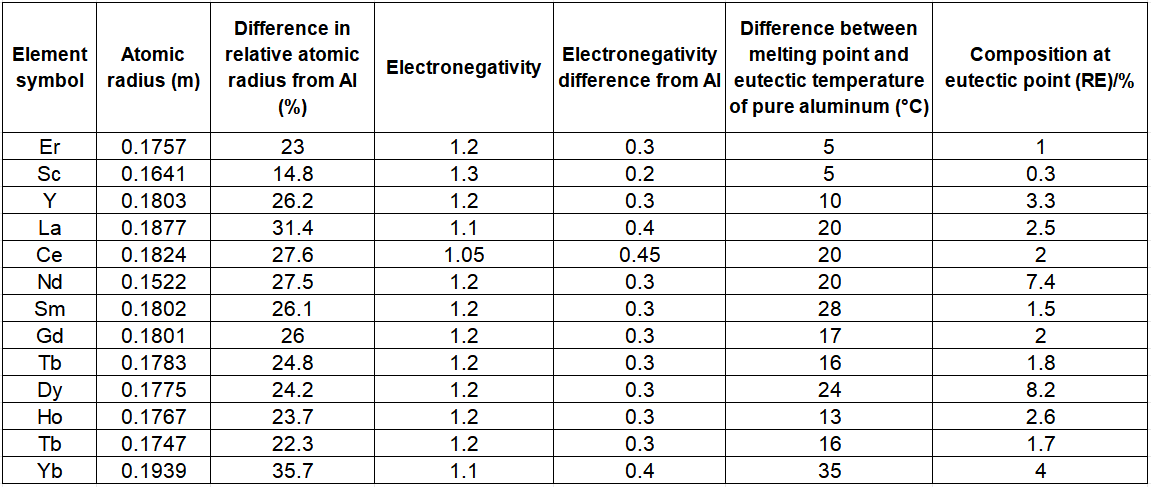

Njirimara nke ihe ndị bụ isi na-adịghị ahụkebe ụwa na njirimara ha na aluminom

Oge nzipu: Ọgọst-21-2025