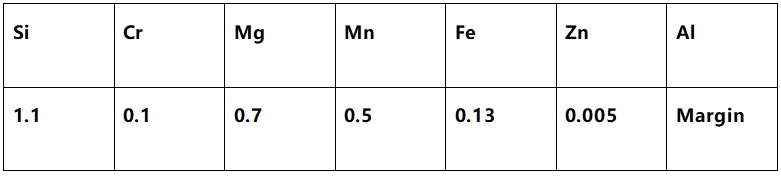

1. Alloy mejupụtara

2. Usoro homogenization

390 ℃ x mkpuchi maka 1.0h + 575 ℃ x mkpuchi maka 8h, ifufe siri ike jụrụ na 200 ℃ wee mee ka mmiri dị jụụ.

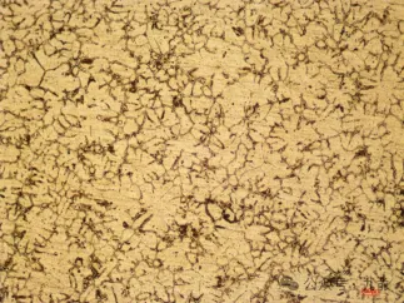

3. Metallographic Structure

Nhazi 1 Metallographic Ọdịdị nke isi nke 6082 alloy ingot, nke Keller reagent debere, nwere dendrites emepụtara nke ọma.

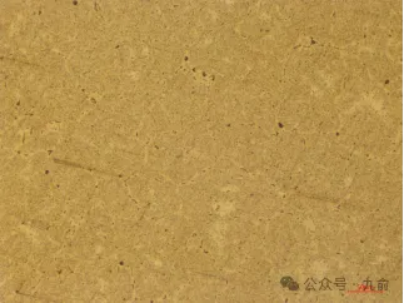

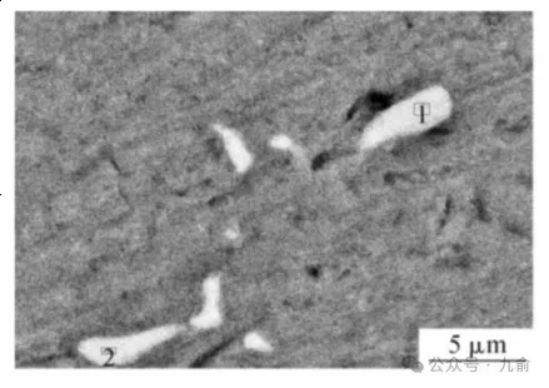

Nhazi 2 Metallographic Ọdịdị nke isi nke 6082 alloy ingot, nke Keller reagent debere, na nhazi mgbe ngwọta siri ike gasịrị.

4. Mmetụta nke homogenization okpomọkụ ọgwụgwọ na alloy Ọdịdị

4.1 Dị ka egosiri na eserese 1, alloy nwere dendrites emepụtara nke ọma na steeti nkedo, na enwere ọnụ ọgụgụ buru ibu nke netwọkụ na-enweghị nha nha nha nha na oke oke ọka.

4.2 Ebe ọ bụ na ihe na-agbaze nke ihe dị iche iche dị iche iche mgbe alloy siri ike, ihe mgbagwoju anya nke usoro a na-eduga n'usoro solute solute n'ime kristal, nke a na-egosipụta kpọmkwem na ọgbọ nke ọnụ ọgụgụ buru ibu nke netwọk mmiri ozuzo na oke ọka.

4.3 Na microstructure mgbe ọgwụgwọ homogenization (Figure 2), ọnụ ọgụgụ nke precipitated n'ụzọ na ọka ókè na-ukwuu ebelata, na ọka size na-abawanye synchronously. Nke a bụ n'ihi na mgbasawanye nke atọm na-abawanye n'okpuru okpomọkụ dị elu, mkpochapụ nkewa na mgbasa nke na-abụghị nke nha na-eme na ingot, na ogige netwọk na oke ọka na-agbaze nke ọma.

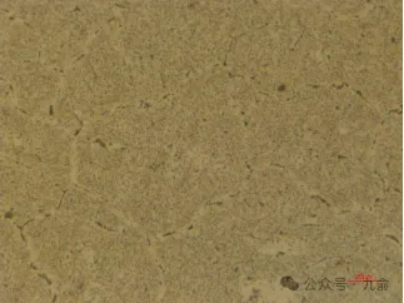

4.4 Site na nyocha SEM, dị ka egosiri na FIG3, a na-ahọrọ akụkụ dị iche iche nke oge a na-agbapụta maka nyocha EDS, na-akwado na usoro a na-agbapụta bụ Al (MnFe) Si.

4.5 N'oge nkedo alloy, a na-emepụta oke mmiri nke nwere Mn, ma na-edobe akụkụ ya na ngwọta siri ike karịrị akarị. Mgbe oke okpomọkụ na ogologo oge homogenization ọgwụgwọ, na Mn supersaturated na matrix precipitates n'ụdị Mn-nwere ogige, nke na-egosipụta dị ka ọnụ ọgụgụ buru ibu nke gbasasịrị Mn-nwere compound decomposition participitated precipitated na crystal (Figure 2).

4.6 Ebe ọ bụ na usoro awụsara ahụ nwere Mn element, ọ nwere nkwụsi ike dị mma. Site na mmụba nke mgbasa ozi atọm, akụkụ akụkụ Al (MnFe) Si ji nwayọọ nwayọọ na-egosi njirimara spheroidization.

Fig.3 Al(MnFe) Si phase na 6082 alloy

5. Mmetụta nke ngwọta ịka nká usoro na n'ibu Njirimara

Mgbe homogenization, netwọk precipitated frasi mbụ na ọka ókè nke 6082 alloy na-etisasịwo, nke nwere ike melite keukwu n'ibu Njirimara nke sample. N'otu oge ahụ, usoro Al(MnFe) Si na-eguzogide okpomọkụ na-esiwanye ike, nke nwere ike ime ka ọ dị mma. Nke a na-egosi na arụmọrụ zuru oke nke ihe a ga-eme ka ọ dịkwuo mma mgbe ọgwụgwọ okpomọkụ homogenization gasịrị.

6. Nkwubi okwu

6.1 6082 aluminum alloy ingot nwere dendrites emepụtara nke ọma na ọnụ ọgụgụ buru ibu nke netwọk na-enweghị nha nha nha nha na oke ọka.

6.2 Mgbe ọgwụgwọ homogenization gasịrị, nyocha nke microscopic gosipụtara na ọnụ ọgụgụ nke usoro a na-agbapụta agbagoro na-ebelata nke ukwuu, na nha ọka na-abawanye synchronously. Mwepụ nkewa na mgbasa nke na-abụghị nha nha mere na ingot, na ogige netwọk dị na oke ọka na-agbaze n'akụkụ.

6.3 Mgbe ị na-eme ihe 6082 alloy, a na-emepụta usoro mmiri ozuzo Al(MnFe) Si. Oge mmiri ozuzo a nwere ihe Mn ma nwee nkwụsi ike dị mma. Dị ka usoro homogenization na-aga n'ihu, akụkụ mmiri ozuzo na-eji nwayọọ nwayọọ na-egosi njirimara spheroidization. A na-agbasasịkwa ụmụ irighiri ihe ndị nwere Mn a n'otu n'otu ma na-ebuli ya na kristal.

6.4 Mgbe ọgwụgwọ homogenization gasịrị, mgbasa nke netwọk na-ebute ụzọ na-egosi na a na-emeziwanye arụmọrụ nke ingot dum mgbe ọgwụgwọ okpomọkụ homogenization gasịrị.

Oge nzipu: Jun-08-2025