6063 aluminum alloy bụ nke Al-Mg-Si usoro okpomọkụ na-edozi aluminom alloy. Ọ nwere ọmarịcha extrusion ịkpụzi arụmọrụ, ezi corrosion eguzogide na keukwu n'ibu Njirimara. A na-ejikwa ya n'ọtụtụ ebe na ụlọ ọrụ ụgbọ ala n'ihi agba agba oxidation ya dị mfe. Site na mmụba nke usoro ụgbọ ala dị arọ, ngwa nke 6063 aluminum alloy extrusion ihe na ụlọ ọrụ ụgbọ ala abawanyela n'ihu.

A na-emetụta microstructure na ihe onwunwe nke ihe ndị na-emepụta ihe site na ngwakọta nke ngwa ngwa extrusion, okpomọkụ extrusion na extrusion ratio. N'ime ha, a na-ekpebi oke extrusion site na nrụgide extrusion, nrụpụta mmepụta na akụrụngwa mmepụta. Mgbe ọnụọgụ extrusion dị ntakịrị, nrụrụ alloy dị ntakịrị na nhazigharị microstructure adịghị anya; ịba ụba extrusion ruru nwere ike nụchaa ọka nke ukwuu, gbajie akụkụ nke abụọ na-enweghị isi, nweta microstructure edo edo, ma melite akụrụngwa akụrụngwa nke alloy.

6061 na 6063 aluminum alloys na-enweta recrystallization siri ike n'oge usoro extrusion. Mgbe okpomọkụ nke extrusion na-adịgide adịgide, dị ka ọnụọgụ extrusion na-abawanye, nha ọka na-ebelata, a na-agbasasị usoro ike ike nke ọma, na ike ike na elongation nke alloy na-abawanye otú ahụ; Otú ọ dị, ka ọnụ ọgụgụ nke extrusion na-abawanye, ike nke extrusion nke a chọrọ maka usoro nkwụsị ahụ na-abawanye, na-eme ka mmetụta okpomọkụ dị ukwuu, na-eme ka okpomọkụ dị n'ime nke alloy na-ebili, na arụmọrụ nke ngwaahịa ahụ na-ebelata. Nnwale a na-amụ mmetụta nke extrusion ratio, karịsịa nnukwu extrusion ruru, na microstructure na n'ibu Njirimara nke 6063 aluminum alloy.

1 Ngwa na ụzọ nnwale

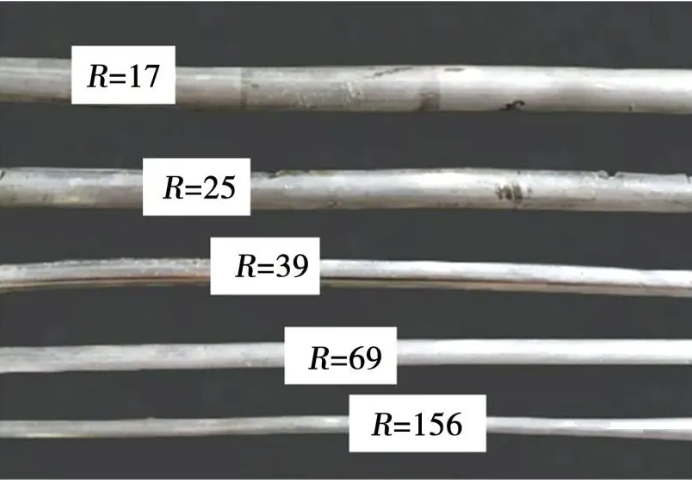

Ihe nnwale ahụ bụ 6063 aluminum alloy, na ihe mejupụtara kemịkalụ gosipụtara na tebụl 1. The mbụ size nke ingot bụ Φ55 mm × 165 mm, na-esichara n'ime extrusion billet na size nke Φ50 mm × 150 mm mgbe ọgwụgwọ homogenization na 560 ℃ maka 6 h. A na-ekpo ọkụ billet ahụ ruo 470 ℃ ma na-ekpo ọkụ. The preheating okpomọkụ nke extrusion gbọmgbọm bụ 420 ℃, na preheating okpomọkụ nke ebu bụ 450 ℃. Mgbe extrusion ọsọ (extrusion mkpanaka na-akpụ akpụ ọsọ) V = 5 mm / s na-anọgide na-agbanweghị, 5 ìgwè dị iche iche extrusion ratio ule na-rụrụ, na extrusion ratios R bụ 17 (kwekọrọ na anwụ oghere dayameta D = 12 mm), 25 (D = 10 mm), 39 (D = 8 mm), 69 (D = 6 mm), na (D = 6 mm).

Isiokwu 1 Chemical mejupụtara nke 6063 Al alloy (wt/%)

Mgbe a na-egweri akwụkwọ aja na nchacha igwe, ihe nlele metallographic ka ejiri HF reagent nwere obere olu nke 40% maka ihe dị ka 25 s, a na-ahụkwa usoro metallographic nke ihe nlele ahụ na microscope anya LEICA-5000. A na-ebipụ ihe nlele nyocha ederede nke nwere nha 10 mm × 10 mm site na etiti akụkụ ogologo ogologo nke mkpanaka ahụ, a na-egweri igwe na etching iji wepụ oyi akwa nrụgide elu. Ọnụọgụ mkpanaka ezughị ezu nke ụgbọ elu kristal atọ {111}, {200}, na {220} nke nlele ahụ bụ nke X′Pert Pro MRD X-ray diffraction analyzer nke ụlọ ọrụ PANalytical tụlere ya, yana X′Pert Data View na software X′Pert Texture debere ma nyochaa data ederede.

A na-ewepụta ihe atụ nke ihe nkedo nke ihe nkedo ahụ site na etiti nke ingot, a na-egbutukwa ihe nkedo ahụ n'akụkụ ntụziaka extrusion mgbe a kpochapụrụ ya. Ogo ebe nlele bụ Φ4 mm×28 mm. A na-eji igwe nyocha SANS CMT5105 nke ihe nleba anya zuru ụwa ọnụ nke nwere ọnụọgụ 2 mm / min. A gbakọrọ nkezi uru nke ụdị ọkọlọtọ atọ dị ka data akụrụngwa akụrụngwa. A na-ahụ nhụsianya mgbawa nke ihe nlere anya site na iji eletrọn microscope na-enyocha ala dị ala (Quanta 2000, FEI, USA).

2 Nsonaazụ na mkparịta ụka

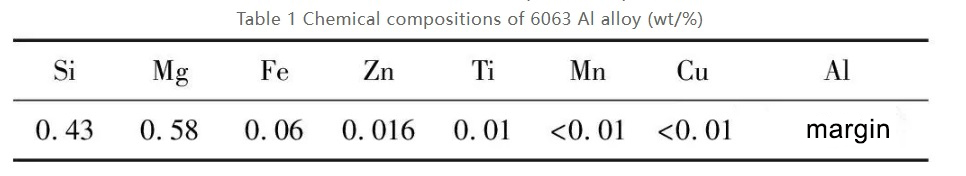

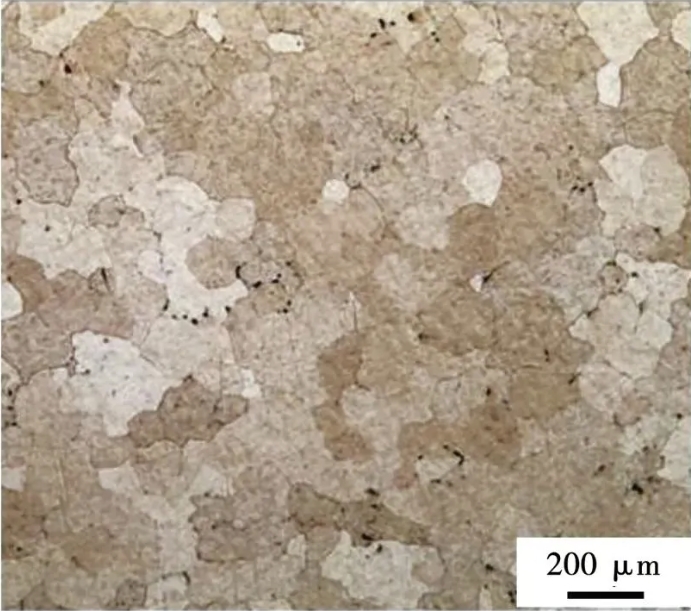

Ọgụgụ 1 na-egosi metallographic microstructure nke ihe nkedo 6063 aluminum alloy tupu na mgbe ọgwụgwọ homogenization. Dị ka egosiri na eserese 1a, mkpụrụ ọka α-Al dị na microstructure dị ka nkedo dị iche na nha, ọnụ ọgụgụ buru ibu nke reticular β-Al9Fe2Si2 na-ezukọ na oke ọka, na ọnụ ọgụgụ buru ibu nke usoro Mg2Si granular dị n'ime ọka. Mgbe ingot e homogenized na 560 ℃ maka 6 h, ndị na-abụghị nha nha eutectic oge n'etiti alloy dendrites ji nwayọọ nwayọọ gbazee, alloy ọcha etisasịwo n'ime matrix, na microstructure bụ edo, na nkezi ọka size bụ banyere 125 μm (Figure 1b).

Tupu homogenization

Mgbe edozichara ọgwụgwọ na 600 Celsius C maka awa 6

Fig.1 Metallographic Ọdịdị nke 6063 aluminum alloy tupu na mgbe homogenization ọgwụgwọ

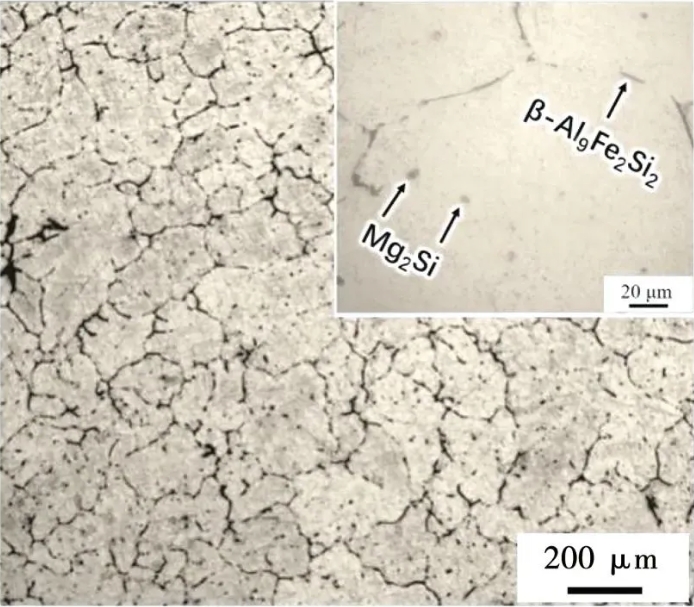

Ọgụgụ 2 na-egosi mpụta nke 6063 aluminum alloy bars nwere oke extrusion dị iche iche. Dị ka e gosiri na Figure 2, elu àgwà nke 6063 aluminum alloy Ogwe extruded na dị iche iche extrusion ratios dị mma, karịsịa mgbe extrusion ratio na-abawanye na 156 (kwekọrọ na mmanya extrusion outlet ọsọ nke 48 m / min), a ka na-enweghị extrusion ntụpọ dị ka cracks na peeling n'elu elu nke mmanya, na-enwekwa 6 extrusion na-arụ ọrụ nke ọma n'okpuru 60. nnukwu ọsọ na nnukwu extrusion ruru.

Fig.2 Ọdịdị nke 6063 aluminum alloy mkpara na dị iche iche extrusion oke

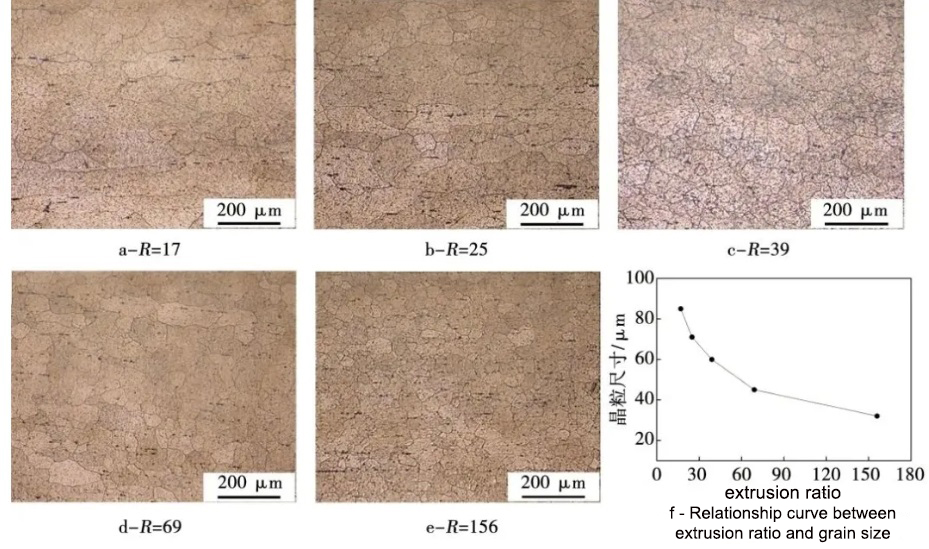

Ọgụgụ 3 na-egosi microstructure metallographic nke akụkụ ogologo nke 6063 aluminum alloy bar nwere oke extrusion dị iche iche. Usoro ọka nke mmanya ahụ nwere oke extrusion dị iche iche na-egosi ogo dị iche iche nke elongation ma ọ bụ nhazigharị. Mgbe ọnụọgụ extrusion bụ 17, a na-agbatị mkpụrụ ọka mbụ n'akụkụ ntụziaka extrusion, na-esonyere ya na nhazi nke obere mkpụrụ osisi recrystallized, ma ọka ndị ahụ ka na-adịchaghị njọ, na nkezi ọka nke ihe dị ka 85 μm (Figure 3a); mgbe oke extrusion bụ 25, a na-adọta ọka ndị ọzọ dị gịrịgịrị, ọnụ ọgụgụ nke mkpụrụ osisi recrystallized na-abawanye, na nkezi nke ọka na-ebelata ruo ihe dị ka 71 μm (Figure 3b); mgbe extrusion ruru bụ 39, ma e wezụga n'ihi na a obere ọnụ ọgụgụ nke oruru grains, na microstructure bụ ihu ọma mejupụtara equiaxed recrystallized grains nke na-ekwekọghị ekwekọ size, na nkezi ọka size nke banyere 60 μm (Nyocha 3c); mgbe extrusion ruru bụ 69, na ike recrystallization usoro bụ ihu ọma dechara, na keadighi rarii mbụ grains e kpamkpam ghọọ uniformly ahaziri recrystallized grains, na nkezi ọka size nụchara anụcha banyere 41 μm (Ọgụgụ 3d); mgbe extrusion ruru bụ 156, na n'ụzọ zuru ezu na-aga n'ihu nke ike recrystallization usoro, na microstructure bụ ọzọ edo, na ọka size bụ nke ukwuu nụchara anụcha banyere 32 μm (Figure 3e). Site na mmụba nke extrusion ruru, usoro recrystallization dị ike na-aga n'ihu n'ụzọ zuru oke, microstructure alloy na-aghọwanye otu, na nha ọka na-anụcharịrị nke ukwuu (Njirimara 3f).

Fig.3 Metallographic Ọdịdị na ọka size nke longitudinal ngalaba nke 6063 aluminum alloy mkpara dị iche iche extrusion oke.

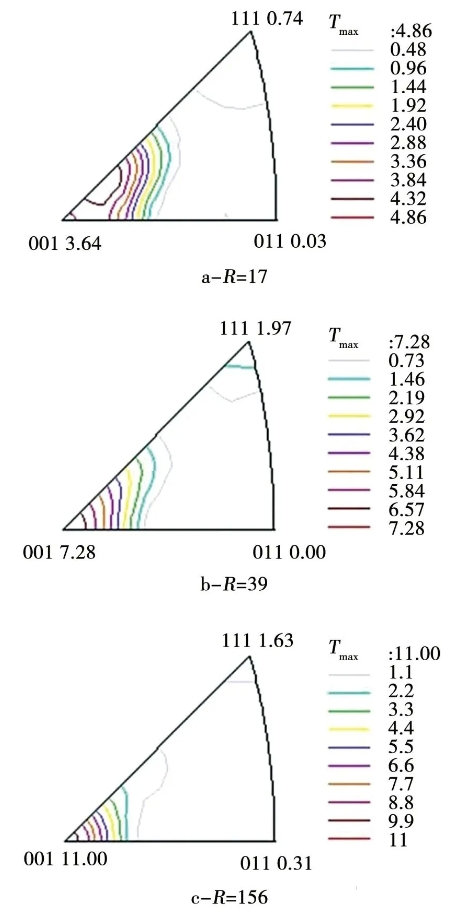

Onyonyo 4 na-egosi ọnụọgụ okporo ụzọ nke 6063 aluminum alloy bars nwere oke extrusion dị iche iche n'akụkụ ụzọ extrusion. Enwere ike ịhụ na microstructures nke ogwe alloy nwere oke extrusion dị iche iche na-emepụta nghazi mmasị doro anya. Mgbe ọnụọgụ extrusion bụ 17, a na-emepụta ihe na-esighị ike <115>+ <100> (Figure 4a); mgbe extrusion ruru bụ 39, udidi components bụ tumadi ike <100> udidi na a obere ego nke adịghị ike <115> udidi (Nyocha 4b); mgbe extrusion ruru bụ 156, texture components bụ <100> udidi na budata ụba ike, mgbe <115> udidi na-apụ n'anya (Figure 4c). Nnyocha egosiwo na ọla ndị nwere cubic na-eche ihu na-abụkarị <111> na <100> textures waya n'oge extrusion na eserese. Ozugbo ederede e hiwere, ụlọ okpomọkụ n'ibu Njirimara nke alloy na-egosi doro anya anisotropy. Ike udidi na-abawanye site na mmụba nke oke extrusion, na-egosi na ọnụ ọgụgụ nke ọka n'otu akụkụ kristal yiri nke extrusion direction na alloy ji nwayọọ nwayọọ na-abawanye, na ogologo ike tensile nke alloy na-abawanye. The usoro ike nke 6063 aluminum alloy ọkụ extrusion ihe na-agụnye ezi ọka ike, dislocation ike, texture ike, wdg N'ime nso nke usoro parameters eji na nke a nnwale ọmụmụ, na-amụba extrusion ruru nwere a na-akwalite mmetụta na n'elu ike usoro.

Fig.4 Reverse osisi eserese nke 6063 aluminum alloy mkpanaka dị iche iche extrusion ruru tinyere extrusion direction

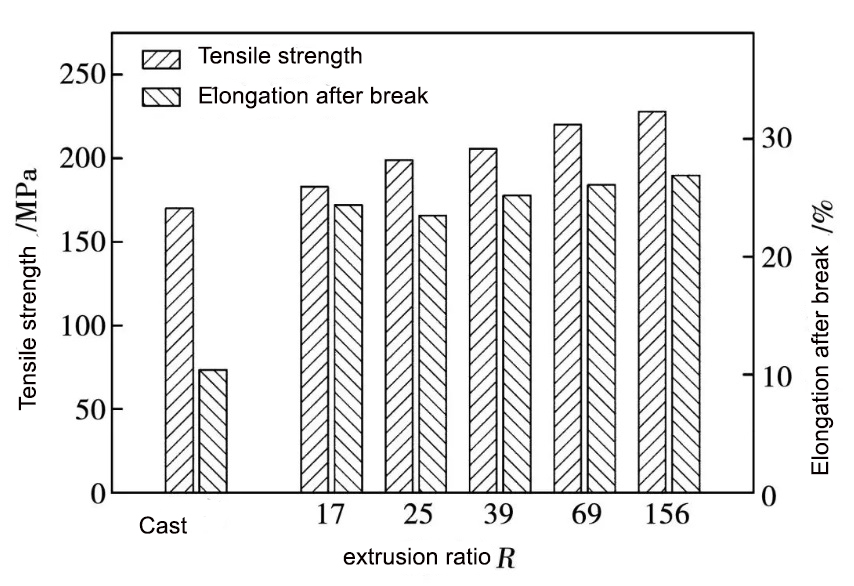

Ọgụgụ 5 bụ histogram nke akụrụngwa tensile nke 6063 aluminum alloy mgbe nrụrụ dị na oke extrusion dị iche iche. Ike ike nke ihe nkedo bụ 170 MPa na elongation bụ 10.4%. A na-emeziwanye ike ike na elongation nke alloy mgbe extrusion gasịrị, na ike ike na elongation ji nwayọọ nwayọọ na-abawanye na mmụba nke oke extrusion. Mgbe ọnụọgụ extrusion bụ 156, ike na-agba ọsọ na elongation nke alloy ruru oke uru, nke bụ 228 MPa na 26.9%, n'otu n'otu, nke dị ihe dịka 34% dị elu karịa ike ike nke ihe nkedo na ihe dịka 158% dị elu karịa elongation. The tensile ike nke 6063 aluminum alloy nwetara site na nnukwu extrusion ruru dị nso na tensile ike uru (240 MPa) nwetara site 4-pass hà channel angular extrusion (ECAP), nke dị nnọọ elu karịa tensile ike uru (171.1 MPa) nwetara site 1-agafe ECAP extrusion nke 6063 aluminum alloy. Ọ nwere ike hụrụ na a nnukwu extrusion ruru nwere ike melite n'ibu Njirimara nke alloy ruo n'ókè ụfọdụ.

The nkwalite nke n'ibu Njirimara nke alloy site extrusion ruru tumadi na-abịa site na nnụcha ọka. Ka ọnụ ọgụgụ extrusion na-abawanye, a na-anụcha ọka ndị ahụ na njupụta dislocation na-abawanye. Oke oke ọka n'otu mpaghara nwere ike igbochi mmegharị nke dislocations nke ọma, jikọtara ya na mmegharị nke ibe ya na ntinye nke dislocations, si otú ahụ meziwanye ike nke alloy. Ka ọka dị mma karị, ka oke oke ọka na-ata ahụhụ, na nrụrụ plastik nwere ike ịgbasa n'ọtụtụ ọka, nke na-adịghị mma maka ịmepụta mgbawa, ka ọ bụrụ na ọ na-agbasawanye. Enwere ike itinyekwu ume n'oge usoro mgbaji, si otú ahụ na-eme ka plasticity nke alloy dịkwuo mma.

Fig.5 Tensile Njirimara nke 6063 aluminum alloy mgbe nkedo na extrusion

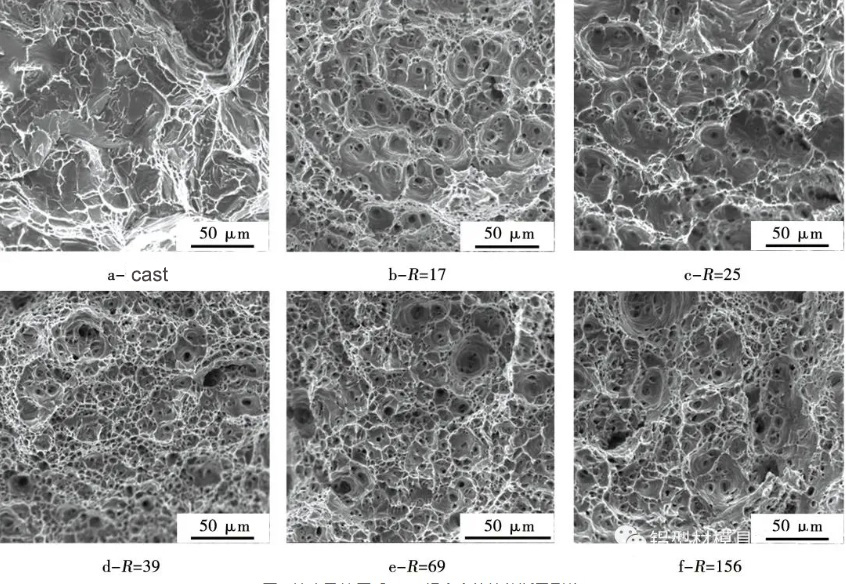

The tensile fracture morphology nke alloy mgbe deformation na dị iche iche extrusion oke gosiri na Figure 6. Ọ dịghị dimples hụrụ na mgbaji morphology nke dị ka-nkedo sample (Onyonyo 6a), na mgbaji ahụ bụ tumadi esịnede ewepụghị ebe na-adọka n'ọnụ, na-egosi na tensile mgbaji mgbaji usoro nke dị ka-nkedo brittlely bụ isi. Ọdịdị nke mgbawa nke alloy mgbe extrusion agbanweela nke ukwuu, na mgbaji na-agụnye ọnụ ọgụgụ dị ukwuu nke dimples equiaxed, na-egosi na usoro mgbaji nke alloy mgbe extrusion gbanwere site na mgbawa na-agbaji agbaji na ọkpụkpụ ductile. Mgbe oke extrusion dị ntakịrị, dimples na-emighị emi na dimple size bụ nnukwu, na nkesa bụ nke na-adịghị mma; dị ka extrusion ratio na-abawanye, ọnụ ọgụgụ nke dimples na-abawanye, dimple size bụ obere na nkesa bụ edo (Nyocha 6b ~ f), nke pụtara na alloy nwere mma plasticity, nke kwekọrọ na n'ibu Njirimara ule pụta n'elu.

3 Nkwubi okwu

N'ime nnwale a, a na-enyocha mmetụta nke oke extrusion dị iche iche na microstructure na ihe onwunwe nke 6063 aluminum alloy n'okpuru ọnọdụ na nha billet, ingot okpomọkụ okpomọkụ na extrusion ọsọ adịghị agbanwe agbanwe. Nkwubi okwu ndị a bụ:

1) Mgbanwe recrystallization na-eme na 6063 aluminum alloy n'oge extrusion ọkụ. Na mmụba nke extrusion ruru, ọka na-anọgide na-anụcha, na ọka elongated tinyere extrusion direction na-agbanwe n'ime equiaxed recrystallized grains, na ike nke <100> waya udidi na-anọgide na-abawanye.

2) N'ihi mmetụta nke ezi ọka na-ewusi ike, a na-emezi ihe ndị na-emepụta ihe nke alloy na mmụba nke extrusion ratio. N'ime nso nke ule parameters, mgbe extrusion ruru bụ 156, tensile ike na elongation alloy ruru kacha ụkpụrụ nke 228 MPa na 26,9% n'otu n'otu.

Fig.6 Tensile fracture morphologies nke 6063 aluminum alloy mgbe nkedo na extrusion

3) Ụdị mgbawa nke ihe nkedo dị ka ihe nkedo bụ ebe dị larịị na akụkụ akwa akwa. Mgbe extrusion, mgbaji ahụ na-agụnye ọnụ ọgụgụ buru ibu nke dimples equiaxed, na usoro mgbaji na-agbanwe site na mgbaji na-agbaji agbaji gaa na ọkpụkpụ ductile.

Oge nzipu: Nov-30-2024