Anodizing bụ usoro eji emepụta ihe nkiri aluminom oxide n'elu ngwaahịa aluminom ma ọ bụ aluminum alloy.Ọ na-agụnye itinye aluminom ma ọ bụ aluminum alloy ngwaahịa dị ka anode na ngwọta electrolyte na itinye ọkụ eletrik na-emepụta ihe nkiri aluminum oxide.Anodizing na-eme ka nguzogide corrosion dịkwuo mma, nguzogide iyi, na ihe ịchọ mma nke profaịlụ aluminom.N'oge usoro anodizing nke profaịlụ aluminom, ọtụtụ njirimara ntụpọ nwere ike ime.Ka anyị buru ụzọ ghọta ihe kpatara ntụpọ ntụpọ.Nrụrụ ihe, mmetọ ịsa ahụ, ọdịda nke akụkụ abụọ nke alloy, ma ọ bụ mmetụta galvanic nwere ike bute ntụpọ ndị ahụrụ anya.A kọwara ha dịka ndị a:

1.Acid ma ọ bụ alkali etching

Tupu anodizing, ihe aluminom nwere ike mebie site na acid ma ọ bụ mmiri mmiri alkaline, ma ọ bụ na-emetụta uzuzu acid ma ọ bụ alkaline, na-ebute ntụpọ ọcha na mpaghara n'elu.Ọ bụrụ na nrụrụ ahụ siri ike, nnukwu oghere nwere ike ịmalite.Ọ na-esiri ike iji anya gba ọtọ chọpụta ma ọ bụ acid ma ọ bụ alkali kpatara mmebi ahụ, mana enwere ike ịmata ya n'ụzọ dị mfe site n'ikiri akụkụ akụkụ nke ebe mebiri emebi n'okpuru microscope.Ọ bụrụ na ala nke olulu bụ gburugburu na-enweghị intergranular corrosion, ọ na-eme site alkali etching.Ọ bụrụ na ala na-adịghị ahụkebe ma na-esonyere ya na corrosion intergranular, na olulu miri emi, ọ na-akpata acid etching.Nchekwa na-ezighị ezi na njikwa na ụlọ ọrụ mmepụta ihe nwekwara ike iduga ụdị corrosion a.Uzuzu acid sitere na ihe na-eme ka ihe na-egbu egbu ma ọ bụ uzuoku acid ndị ọzọ, yana chlorinated organic degenreasers, bụ isi mmalite acid etching.Ihe na-akpata etching alkali a na-ahụkarị bụ mkpọsa na mwụsa nke ngwa agha, ash ciment, na mmiri mmiri na-asa alkaline.Ozugbo ekpebie ihe kpatara ya, iwusi njikwa nke usoro dị iche iche na ụlọ ọrụ mmepụta ihe nwere ike idozi nsogbu ahụ.

2.Atmospheric corrosion

Profaịlụ aluminom ekpughere n'ikuku iru mmiri nwere ike ịmalite ntụpọ ọcha, nke na-adakọkarị ogologo oge n'ahịrị ebu.Ikuku corrosion n'ozuzu adịghị ike dị ka acid ma ọ bụ alkali etching na ike wepụ site n'ibu ụzọ ma ọ bụ alkaline ịsacha.Ikuku corrosion na-abụkarị nke na-abụghị ebe ma na-emekarị na-eme n'elu ụfọdụ elu, dị ka ala okpomọkụ ebe ikuku mmiri na-adị mfe condensed ma ọ bụ n'elu elu.Mgbe corrosion nke ikuku na-akawanye njọ, akụkụ obe nke oghere ndị ahụ na-apụta dị ka ero tụgharịrị.N'okwu a, ịsacha alkaline enweghị ike iwepụ ntụpọ ndị ahụ ma nwee ike gbasaa ha.Ọ bụrụ na ekpebie corrosion ikuku, ọnọdụ nchekwa dị na ụlọ nrụpụta kwesịrị ịlele.E kwesịghị ịchekwa ihe aluminom n'ebe ndị nwere oke okpomọkụ dị ala iji gbochie ikuku mmiri.Ebe nchekwa kwesịrị ịbụ nkụ, na okpomọkụ kwesịrị ịdị ka otu dị ka o kwere mee.

3.Paper corrosion (mmiri tụrụ)

Mgbe etinyere akwụkwọ ma ọ bụ kaadiboodu n'etiti ihe aluminom ma ọ bụ jiri maka nkwakọ ngwaahịa, ọ na-egbochi abrasion.Otú ọ dị, ọ bụrụ na akwụkwọ ahụ aghọọ mmiri, ntụpọ corrosion na-apụta n'elu aluminum.Mgbe a na-eji kaadiboodu corrugated eme ihe, ahịrị ntụpọ corrosion mgbe niile na-apụta n'ebe a na-akpakọrịta na bọọdụ corrugated.Ọ bụ ezie na enwere ike ịhụ ntụpọ mgbe ụfọdụ n'elu aluminom, a na-akpọkarị ha mgbe ịsachara alkaline na anodizing.Ebe ndị a na-adịkarị omimi ma sie ike iwepụ site na n'ibu ụzọ ma ọ bụ ịsacha alkaline.A na-akpata corrosion akwụkwọ (osisi osisi) site na ion acid, tumadi SO42- na Cl-, nke dị na akwụkwọ ahụ.Ya mere, iji akwụkwọ (osisi) na-enweghị chlorides na sulfates na izere ịbanye mmiri bụ ụzọ dị irè iji gbochie akwụkwọ (osisi) corrosion.

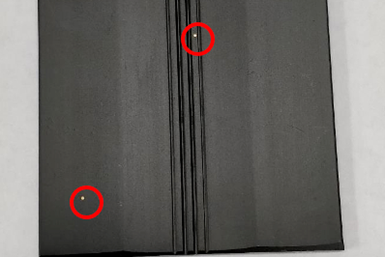

4.Cleaning mmiri corrosion (a makwaara dị ka snowflake corrosion)

Mgbe ịsachara alkaline, polishing chemical, ma ọ bụ sulfuric acid pickling, ọ bụrụ na mmiri nchacha nwere adịghị ọcha, ọ nwere ike ịkpata ntụpọ n'ụdị kpakpando ma ọ bụ na-egbuke egbuke n'elu.Omimi corrosion dị omimi.Ụdị nrụrụ a na-eme mgbe mmiri na-ehicha ihe na-emetọ ya nke ukwuu ma ọ bụ mgbe ọ̀tụ̀tụ̀ mmiri na-asọ asọ dị ntakịrị.Ọ dị ka kristal yiri flake snow n'ọdịdị ya, ya mere aha a na-akpọ "corrosion flake snow."Ihe kpatara ya bụ mmeghachi omume n'etiti adịghị ọcha nke zinc na aluminom na SO42- na Cl- na mmiri nhicha.Ọ bụrụ na mkpuchi nke tank adịghị mma, mmetụta galvanic nwere ike ime ka ntụpọ a dịkwuo njọ.Dị ka isi mmalite si mba ọzọ si kwuo, mgbe ọdịnaya nke Zn na aluminum alloy karịrị 0.015%, Cl- na mmiri nhicha dị elu karịa 15 ppm, ụdị corrosion a nwere ike ime.Iji nitric acid maka pickling ma ọ bụ ịgbakwunye 0.1% HNO3 na mmiri nhicha nwere ike iwepụ ya.

5.Chloride corrosion

Ọnụnọ nke obere chloride n'ime sulfuric acid anodizing bat nwekwara ike iduga n'iyi corrosion.The e ji mara ọdịdị bụ miri oji kpakpando ekara olulu, nke na-na-n'ọnụ na nkuku nke workpiece ma ọ bụ n'ebe ndị ọzọ na elu ugbu densities.Ebe ndị dị n'olulu enweghị ihe nkiri anodized, na ọkpụrụkpụ nke ihe nkiri ahụ na mpaghara "nkịtị" fọdụrụ dị ala karịa uru a tụrụ anya ya.Nnukwu nnu dị n'ime mmiri mgbata bụ isi ihe na-ebute mmetọ n'ime bat.

6.Galvanic corrosion

Na tank ike (anodizing ma ọ bụ electrolytic agba), mmetụta galvanic dị n'etiti workpiece na tank (nkịta ígwè), ma ọ bụ mmetụta nke mmiri na-asọ oyi na tank nke na-adịghị ike (ịchacha ma ọ bụ akara), nwere ike ime ka ma ọ bụ mee ka corrosion pitting dịkwuo njọ.

May Jiang deziri site na MAT Aluminum

Oge nzipu: Dec-15-2023