1. Okwu mmalite

Alloys aluminom nwere ike ọkara na-egosipụta njirimara nhazi dị mma, mmetụ uche, mmetụta siri ike, na nguzogide corrosion. A na-arụ ọrụ nke ọma na ụlọ ọrụ dị iche iche, dị ka ngwá electronic na mmiri, maka ịmepụta ọkpọkọ, mkpanaka, profaịlụ, na wires. Ka ọ dị ugbu a, a na-enwewanye ọchịchọ maka 6082 aluminum alloy mmanya. Iji mezuo ihe ndị ahịa chọrọ na ihe ndị ọrụ chọrọ, anyị mere nnwale na usoro ikpo ọkụ extrusion dị iche iche na usoro ọgwụgwọ okpomọkụ ikpeazụ maka ogwe 6082-T6. Ebumnobi anyị bụ ịchọpụta usoro ọgwụgwọ okpomọkụ nke na-egbo mkpa arụrụ arụ ọrụ maka ụlọ mmanya ndị a.

2.Experimental Materials and Production Process Flow

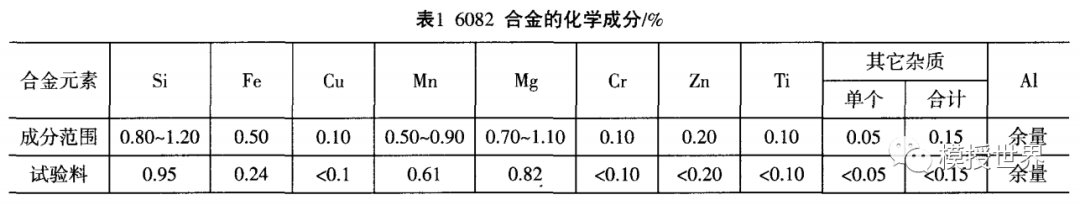

2.1 Ngwa nnwale

A na-emepụta ingots nke nha Ф162×500 site na iji usoro nkedo na-aga n'ihu na-aga n'ihu ma tinye ya na ọgwụgwọ na-abụghị nke uwe. Ogo metallurgical nke ingots kwekọrọ n'ụkpụrụ teknụzụ njikwa ime ụlọ ọrụ. E gosipụtara ihe mejupụtara kemịkalụ nke alloy 6082 na tebụl 1.

2.2 Usoro mmepụta usoro

Ogwe 6082 nnwale ahụ nwere nkọwapụta nke 14mm. Akpa extrusion nwere dayameta nke 170mm nke nwere oghere extrusion 4 na ọnụọgụ extrusion nke 18.5. Usoro a kapịrị ọnụ gụnyere kpo oku ingot, extrusion, quenching, ịgbatị ịgbatị na nlele, nkwụzigharị roller, ịkpụ ikpeazụ, ịka nká, nyocha dị mma, na nnyefe.

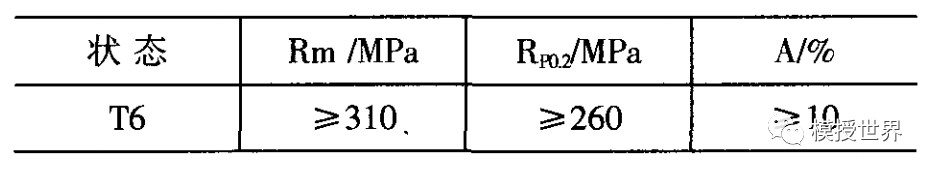

3.Nnwale ebumnobi

Ebumnuche nke ọmụmụ a bụ iji chọpụta usoro usoro ọgwụgwọ okpomọkụ extrusion na njedebe ọgwụgwọ okpomọkụ ikpeazụ nke na-emetụta arụmọrụ nke ogwe 6082-T6, na-emecha nweta ihe achọrọ ọkọlọtọ. Dị ka ụkpụrụ si dị, ihe arụ ọrụ ogologo oge nke alloy 6082 kwesịrị izute nkọwapụta edepụtara na tebụl 2.

4.Experimental Approach

4.1 Nnyocha Ọgwụ Ọkụ Extrusion

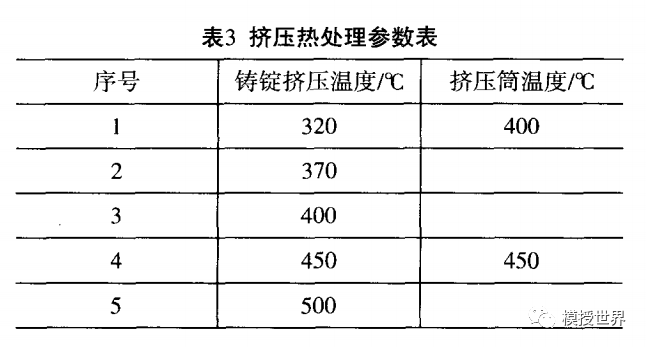

Nchọpụta ọgwụgwọ okpomọkụ extrusion bụ nke lekwasịrị anya na mmetụta nke nkedo ingot extrusion okpomọkụ yana okpomoku akpa extrusion na akụrụngwa. A kọwapụtara nhọrọ ndị a kapịrị ọnụ na Tebụl 3.

4.2 Ngwọta siri ike na nyocha ọgwụgwọ okpomọkụ ịka nká

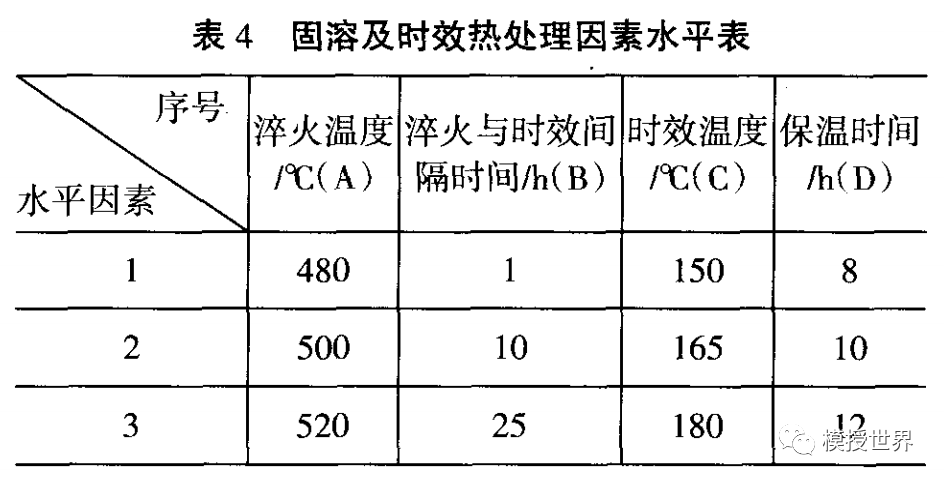

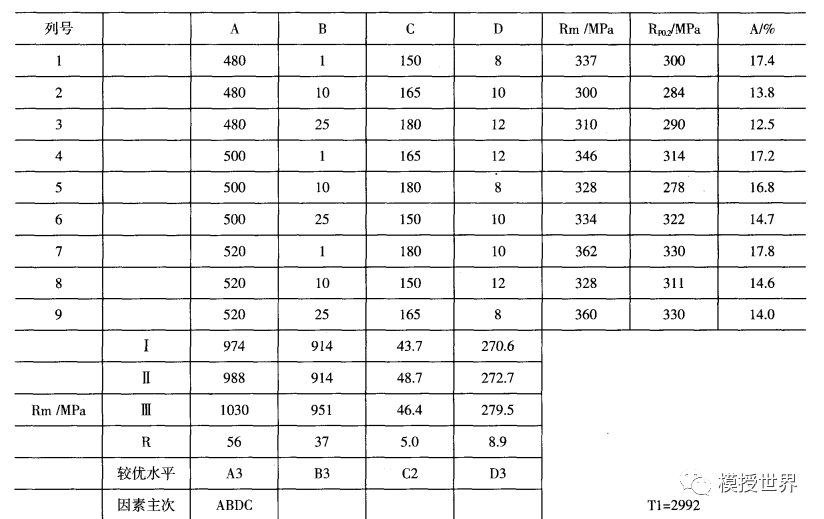

Ejiri usoro nnwale nke orthogonal rụọ ọrụ maka ngwọta siri ike na usoro ọgwụgwọ okpomọkụ ịka nká. A na-enye ọkwa ihe ahọpụtara na Tebụl 4, yana tebụl imewe orthogonal gosipụtara dị ka IJ9(34).

5.Results na Analysis

5.1 Nsonaazụ na nyocha nyocha ọgwụgwọ ọkụ extrusion

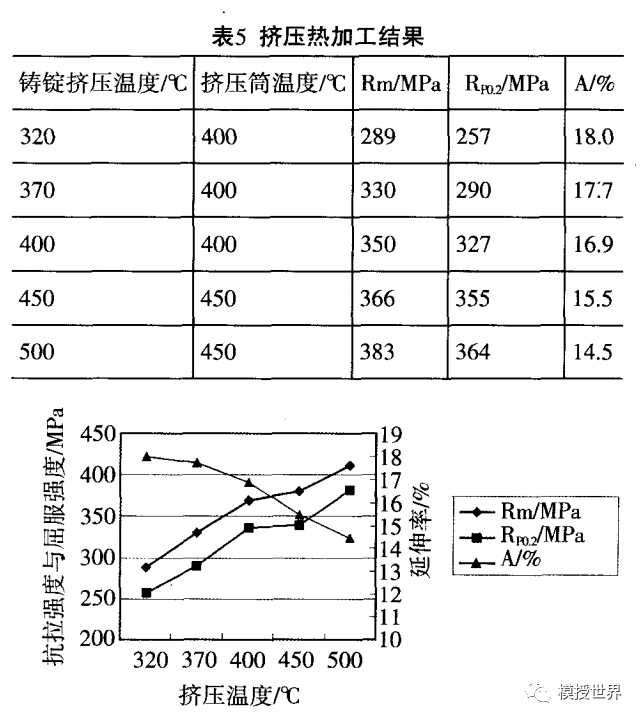

A na-egosi nsonaazụ nke nyocha ọgwụgwọ okpomọkụ extrusion na Tebụl 5 na eserese 1. A na-ewere ihe nlele itoolu maka otu ọ bụla, a na-ekpebikwa usoro arụmọrụ ha. Dabere na nyocha metallographic na ihe mejupụtara kemịkalụ, e guzobere usoro ọgwụgwọ okpomọkụ: quenching na 520 ° C maka nkeji 40 na ịka nká na 165 ° C maka awa 12. Site na Tebụl 5 na eserese 1, enwere ike ịhụ na ka nkedo ingot extrusion okpomọkụ na okpomoku extrusion na-abawanye, ma ike tensile na ike mkpụrụ ji nwayọọ nwayọọ na-abawanye. E nwetara nsonaazụ kacha mma na okpomọkụ extrusion nke 450-500 Celsius C na ihe ọkụ ọkụ nke 450 ° C, nke zutere ihe achọrọ. Nke a bụ n'ihi mmetụta nke ọrụ oyi na-agbasi ike na okpomọkụ nke extrusion dị ala, na-eme ka mgbaji dị n'ókè nke ọka na ụbara ngwọta siri ike n'etiti A1 na Mn n'oge kpo oku tupu emenyụ, na-eduga na recrystallization. Ka okpomọkụ extrusion na-abawanye, ike kachasị Rm nke ngwaahịa ahụ na-akawanye mma. Mgbe okpomoku akpa extrusion rutere nso ma ọ bụ gafere okpomoku ingot, nrụrụ na-ezighi ezi belatara, na-ebelata ịdị omimi nke mgbanaka ọka na-abawanye ma na-abawanye ike mkpụrụ Rm. Ya mere, ihe ezi uche dị na ya maka ọgwụgwọ okpomọkụ extrusion bụ: ingot extrusion okpomọkụ nke 450-500 ° C na extrusion akpa okpomọkụ nke 430-450 ° C.

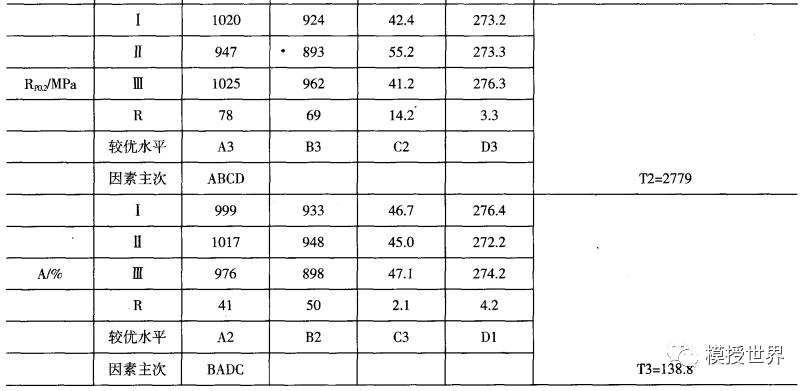

5.2 Ngwọta siri ike na Nsonaazụ nnwale Orthogonal ịka nká na nyocha

Tebụl 6 na-ekpughe na ọkwa kachasị mma bụ A3B1C2D3, na-emenyụ na 520 Celsius C, okpomọkụ nke ịka nká n'etiti 165-170 Celsius C, na oge ịka nká nke awa 12, na-ebute ike dị elu na plasticity nke ogwe. The quenching usoro na-etolite supersaturated siri ike ngwọta. Na ala quenching okpomọkụ, ịta nke supersaturated siri ike ngwọta na-ebelata, na-emetụta ike. Okpomọkụ na-ekpo ọkụ nke ihe dị ka 520 Celsius C na-eme ka mmetụta siri ike na-eme ka ọ kwụsịlata. Ogologo oge dị n'etiti ịka nká na ịka nká, ya bụ, nchekwa ụlọ okpomọkụ, na-emetụta ihe ndị na-emepụta ihe. A na-akpọ nke a karịsịa maka mkpanaka ndị na-adịghị esetịpụ mgbe emenyụchara. Mgbe etiti oge dị n'etiti ịka nká na ịka nká gafere awa 1, ike, ọkachasị ike mkpụrụ, na-ebelata nke ukwuu.

5.3 Metallographic Microstructure Analysis

A na-eme nyocha dị elu na nke polarịịsịsịsịsịsịsịsịsịsịsịsịsịsịsịsịsịsịsịsịsịsịsịsịsịsịsịsịsịsịsịsịsịsịsịsịsịsịsịsịsịsịsịsịsịsịsịsịsịsịsịsịsịsịsịsịsịsịsịsịsịsịsịsịsịsịsịsịsịsịịrịga n'ebe okpomọkụ ngwọta siri ike nke 520°C na 530°C. Foto dị elu gosipụtara oke mmiri ozuzo na-enwe n'ụba n'ụba n'ụkpụrụ na-asọpụta n'ọkwa na-ekesa. Nyocha ọkụ na-ekpo ọkụ na-eji ngwa Axiovert200 gosipụtara ọdịiche dị iche na foto nhazi ọka. Ebe etiti ahụ gosipụtara obere ọka na otu, ebe akụkụ ya gosipụtara ụfọdụ recrystallization na ọka elongated. Nke a bụ n'ihi uto nke kristal nuclei na okpomọkụ dị elu, na-eme ka agịga siri ike dị ka ọnyà.

6.Production Practice Assessment

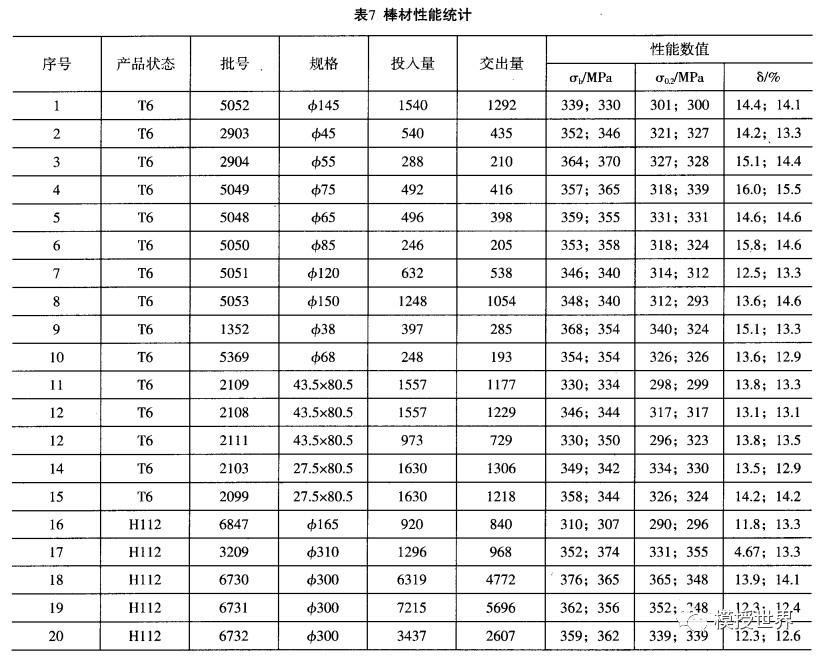

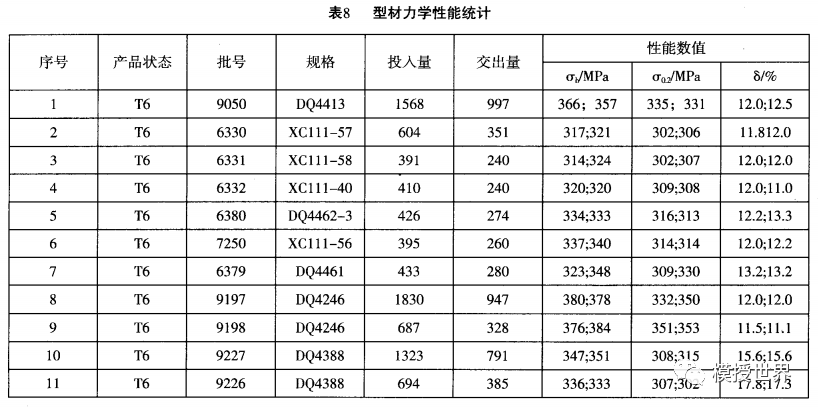

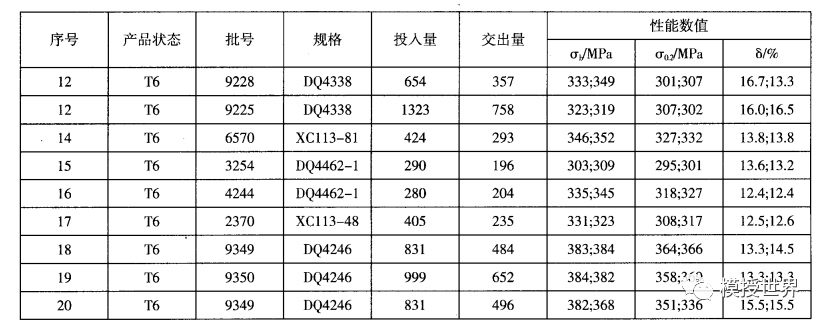

Na mmepụta n'ezie, a na-eduzi ọnụ ọgụgụ arụmọrụ n'ibu na batches 20 nke ụlọ mmanya na batches 20 nke profaịlụ. E gosipụtara nsonaazụ ya na Tebụl 7 na 8. N'ime mmepụta n'ezie, a na-eme usoro extrusion anyị na okpomọkụ nke kpatara T6 steeti samples, na arụ ọrụ arụ ọrụ zutere ụkpụrụ ebumnuche.

7.Mkpebi

(1) Usoro ọgwụgwọ okpomọkụ extrusion: Ingots extrusion okpomọkụ nke 450-500 ° C; extrusion akpa okpomọkụ nke 430-450C.

(2) Usoro ọgwụgwọ okpomọkụ ikpeazụ: Ngwọta ngwọta kachasị mma nke 520-530 ° C; okpomọkụ ịka nká na 165 ± 5 ° C, oge ịka nká nke awa 12; Ogologo oge n'etiti ịka nká na ịka nká ekwesịghị ịfe 1 hour.

(3) Dabere na ntule bara uru, usoro ọgwụgwọ okpomọkụ nke nwere ike ime na-agụnye: extrusion okpomọkụ nke 450-530 ° C, extrusion akpa okpomọkụ nke 400-450 ° C; okpomọkụ ngwọta siri ike nke 510-520 ° C; usoro ịka nká nke 155-170 ° C maka awa 12; enweghị oke kpọmkwem na etiti dị n'etiti ịka nká na ịka nká. Enwere ike itinye nke a n'ime ntuziaka ọrụ usoro.

May Jiang deziri site na MAT Aluminum

Oge nzipu: Mar-15-2024